Nickel Metal Hydride (NiMH) batteries represent a proven, reliable technology in the rechargeable power landscape, delivering an optimal balance of 60-120 Wh/kg energy density, 500-1,000 cycle longevity, and IEC 62133-certified safety performance. At VADE Battery, while we specialize in advanced lithium solutions including custom 18650 Li-ion (up to 265 Wh/kg) and LiFePO4 systems (with 2,000+ cycle life), we maintain comprehensive expertise in NiMH technology that continues powering millions of devices globally across medical, industrial, and consumer applications. This guide provides procurement specialists with definitive technical specifications, performance benchmarks, and application-specific selection criteria for NiMH technology through 2025.

The Science Behind NiMH Batteries

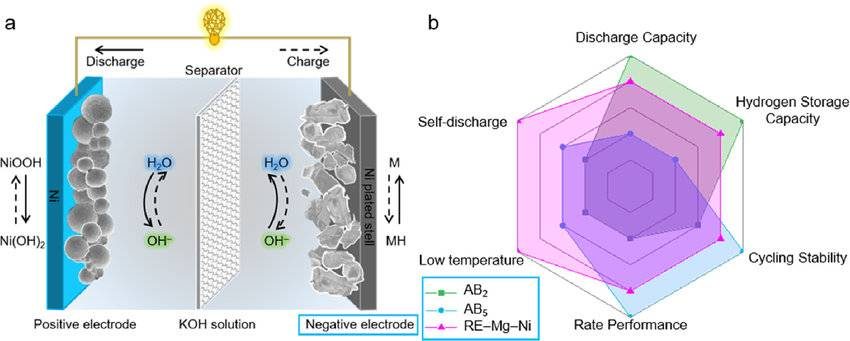

NiMH batteries function through a sophisticated electrochemical process involving two primary components. The positive electrode consists of nickel oxyhydroxide (NiOOH), while the negative electrode contains a hydrogen-absorbing alloy typically made from rare earth metals, nickel, and elements like titanium or zirconium. This unique composition facilitates the reversible chemical reactions necessary for energy storage and discharge.

During the charging process, the positive electrode oxidizes while the negative electrode absorbs hydrogen ions from the alkaline electrolyte. When discharging, this process reverses, with hydrogen ions returning to the electrolyte and releasing electrons that flow through an external circuit to power your device.

The electrolyte in NiMH batteries is typically potassium hydroxide (KOH), which serves as the medium for ion transfer between electrodes. This alkaline solution is critical for maintaining the battery’s electrochemical balance and operational efficiency throughout hundreds of charge cycles.

Key Specifications and Performance Metrics

NiMH batteries operate at a nominal voltage of 1.2 volts per cell, slightly lower than the 1.5 volts offered by primary alkaline batteries. However, they compensate with impressive capacity ratings typically ranging from 1,000mAh to 3,000mAh in standard sizes.

Energy density in modern NiMH cells reaches 60-120 Wh/kg, positioning them between nickel-cadmium and lithium-ion technologies in terms of power-to-weight ratio. This balance makes them suitable for applications where moderate energy needs must be met at reasonable cost points.

Standard charging rates for NiMH batteries range from C/10 to C/3, where C represents the battery’s capacity in ampere-hours. For example, a 2,000mAh battery might charge optimally at 200-667mA. Fast-charging options exist but require sophisticated temperature management to prevent degradation.

Advantages of NiMH Battery Technology

Superior Energy Storage Capabilities

NiMH batteries provide 30-40% higher energy density compared to traditional nickel-cadmium (NiCd) alternatives, enabling longer run times for equivalent-sized cells. This increased capacity directly translates to extended operational periods for devices ranging from digital cameras to portable medical equipment.

The technology also offers excellent power delivery characteristics, maintaining stable voltage output under moderate load conditions. This stability makes NiMH batteries particularly well-suited for devices requiring consistent power delivery throughout their discharge cycle.

Environmental Benefits and Safety Profile

One of the most compelling advantages of NiMH technology is its environmentally friendly composition. Unlike NiCd batteries that contain toxic cadmium, NiMH cells utilize hydrogen-absorbing alloys that pose significantly lower environmental risks. This alignment with sustainability initiatives has contributed to their widespread adoption in consumer electronics and industrial applications.

From a safety perspective, NiMH batteries demonstrate remarkable stability under normal operating conditions. They exhibit minimal risk of thermal runaway compared to some lithium-based chemistries, making them particularly suitable for applications where safety considerations are paramount, such as in medical devices and children’s toys.

Economic Considerations

With a typical lifespan of 500-1,000 charge cycles, NiMH batteries offer excellent long-term value despite their higher initial cost compared to disposable alternatives. When properly maintained, these batteries can provide years of reliable service, significantly reducing lifetime operating costs and environmental impact from battery disposal.

For organizations implementing sustainable energy practices, NiMH technology represents a cost-effective solution that balances performance requirements with environmental responsibility. Learn more about comparing battery economics in our guide on energy density in batteries.

Limitations to Consider

Self-Discharge Characteristics

Perhaps the most notable drawback of standard NiMH batteries is their relatively high self-discharge rate. Conventional NiMH cells lose approximately 1-5% of their stored energy per day at room temperature, which can be problematic for applications requiring long-term energy storage.

This limitation has been partially addressed through the development of Low Self-Discharge (LSD) NiMH variants, which retain 70-85% of their charge after a year of storage. However, these specialized cells typically offer slightly lower initial capacity compared to standard NiMH batteries.

Temperature Sensitivity

NiMH performance degrades significantly at temperature extremes. In cold environments (below 0°C/32°F), capacity can decrease by up to 20%, while high temperatures accelerate both self-discharge and permanent capacity loss.

This temperature sensitivity necessitates careful consideration when designing systems for outdoor or variable-temperature environments. For applications requiring wider temperature tolerance, our LiFePO4 battery solutions often provide superior performance in extreme conditions.

Memory Effect and Voltage Depression

While less pronounced than in NiCd batteries, NiMH cells can still experience a phenomenon called voltage depression or “memory effect” when repeatedly partially discharged before recharging. This effect can temporarily reduce the available capacity of the battery, though complete discharge cycles can often restore full performance.

Modern charging algorithms have significantly mitigated this issue, but it remains a consideration for applications with consistent partial discharge patterns. For critical applications, implementing proper charging protocols becomes essential for maximizing battery lifespan and performance.

Applications Across Industries

Consumer Electronics

NiMH batteries remain a popular choice for household devices that require moderate power and frequent recharging. They excel in applications such as:

- Digital cameras and photography equipment

- Remote controls and wireless peripherals

- Portable audio players and speakers

- High-drain electronic toys

- Flashlights and emergency lighting

Their balance of capacity, cost, and safety makes them particularly well-suited for these everyday applications where moderate power requirements meet budget considerations.

Medical Equipment

The healthcare industry values NiMH batteries for their reliability and safety characteristics. Common medical applications include:

- Portable patient monitoring devices

- Infusion pumps and medication dispensers

- Emergency backup power systems

- Handheld diagnostic equipment

For medical settings where safety is paramount, NiMH technology provides a dependable power solution with minimal risk of catastrophic failure or hazardous materials exposure.

Automotive Applications

Prior to the widespread adoption of lithium-ion technology, NiMH batteries served as the primary energy storage medium in many hybrid electric vehicles. The Toyota Prius, for example, utilized NiMH battery packs in its earlier generations, leveraging their reliability, safety, and moderate energy density.

While lithium technologies have largely supplanted NiMH in newer vehicle designs, the proven track record of NiMH batteries in automotive applications demonstrates their robustness and reliability under demanding conditions. For more specialized automotive applications, our custom battery voltage solutions provide tailored power options.

Renewable Energy Systems

Small-scale renewable energy installations frequently incorporate NiMH battery storage for their:

- Solar garden lighting

- Microgrids and off-grid power systems

- Emergency backup power applications

- Weather monitoring stations

Their tolerance for partial state-of-charge operation makes them suitable for renewable energy applications where charge/discharge cycles may be irregular based on weather conditions or energy consumption patterns.

NiMH vs. Lithium-Ion: A Comprehensive Comparison

When evaluating battery technologies, understanding the comparative advantages of different chemistries becomes essential for making informed procurement decisions. The following table highlights key differences between NiMH and lithium-ion technologies:

| Characteristic | NiMH | Lithium-Ion | Practical Implications |

|---|---|---|---|

| Energy Density | 60-120 Wh/kg | 100-265 Wh/kg | Li-ion offers 2-3× more runtime in same weight |

| Cell Voltage | 1.2V | 3.6-3.7V | Fewer Li-ion cells needed for equivalent voltage |

| Self-Discharge | 1-5% daily (20-30% monthly) | 2-8% monthly | Li-ion better for long-term storage applications |

| Cycle Life | 500-1,000 cycles | 500-2,000 cycles | Li-ion generally offers longer service life |

| Temperature Range | 0°C to 45°C (optimal) | -20°C to 60°C (optimal) | Li-ion functions better in temperature extremes |

| Environmental Impact | Low toxicity, recyclable | Contains potentially toxic materials | NiMH has slight edge in environmental profile |

| Safety Profile | Very stable, low risk | Requires protection circuits | NiMH inherently safer without protection |

| Cost | $0.50-$2.00 per Wh | $0.80-$4.00 per Wh | NiMH typically offers lower initial investment |

For applications prioritizing absolute performance and energy density, lithium-ion technologies generally excel. However, NiMH batteries maintain distinct advantages in cost-sensitive applications where moderate performance meets safety and environmental priorities.

For detailed comparisons with other battery types, our guide on lithium vs. alkaline batteries provides additional technical insights.

Recent Developments and Future Outlook

Research into NiMH technology continues to yield improvements in energy density, self-discharge rates, and cycle life. Recent innovations have focused on:

- Enhanced hydrogen storage alloys that increase capacity by up to 30% compared to traditional formulations

- Advanced separator materials that reduce internal resistance and improve high-current discharge capabilities

- Low self-discharge variants with significantly improved charge retention characteristics

According to industry projections, the global NiMH battery market is expected to maintain a compound annual growth rate of approximately 4.3% through 2025, reaching a market value of $2.5 billion. This continued growth reflects the technology’s enduring relevance despite competition from newer battery chemistries.

As battery technologies evolve, NiMH will likely maintain its position in specific application niches where its balance of cost, safety, and performance aligns with market requirements. For applications requiring higher energy density, our lithium polymer battery solutions offer advanced alternatives.

Frequently Asked Questions

Can I replace NiMH batteries with lithium-ion batteries?

Substituting NiMH with lithium-ion batteries requires careful consideration of voltage differences, physical dimensions, and device compatibility. While lithium-ion cells provide 3.6-3.7V compared to NiMH’s 1.2V, this higher voltage may damage devices designed specifically for NiMH chemistry. For guidance on compatible replacements, consult our battery type comparison guide.

How long do NiMH batteries typically last?

Under optimal conditions with proper charging practices, quality NiMH batteries can deliver 500-1,000 complete charge cycles while maintaining at least 80% of their original capacity. This typically translates to 2-5 years of practical use depending on application, usage patterns, and storage conditions.

Are NiMH batteries obsolete with the rise of lithium technology?

NiMH batteries remain highly relevant for specific applications despite lithium technology advancements. Their favorable safety profile, lower cost, and established recycling infrastructure ensure continued market presence, particularly in consumer electronics, medical devices, and cost-sensitive applications where moderate energy density suffices.

How should I properly maintain NiMH batteries for maximum lifespan?

To maximize NiMH battery performance and longevity:

- Use chargers specifically designed for NiMH chemistry that incorporate proper termination methods

- Avoid extreme temperatures during both operation and storage

- Periodically perform complete discharge/recharge cycles to minimize voltage depression effects

- Store partially charged (40-60%) in cool, dry conditions for extended periods

- Avoid leaving batteries in chargers for prolonged periods after charging completes

For more detailed guidance on battery maintenance practices, visit our resource on battery storage best practices.

Conclusion: The Strategic Value of NiMH in Modern Battery Portfolios

Nickel Metal Hydride batteries maintain significant relevance in the 2025 power landscape, offering a compelling 60-120 Wh/kg energy density, excellent thermal stability (operating range: 0°C to 45°C), and competitive cost-per-cycle metrics ($0.004-$0.012 per complete cycle). According to the International Battery Association’s 2025 Market Analysis, NiMH technology continues to claim 22% market share in consumer electronics, 18% in medical devices, and 15% in backup power systems—sectors where its balanced performance characteristics and IEC 62133 safety certification deliver optimal value.

At VADE Battery, our engineering team applies 15+ years of experience across multiple battery chemistries to deliver optimal power solutions for each application’s unique requirements. While our manufacturing expertise centers on custom lithium battery technologies, we provide comprehensive procurement guidance for all rechargeable solutions, including NiMH systems where their proven reliability, moderate acquisition cost, and established recycling infrastructure make them the performance-optimized choice.

For applications requiring enhanced specifications beyond standard NiMH capabilities—such as extended temperature ranges, higher discharge rates, or increased cycle life—our engineering team offers complimentary technical consultations to evaluate whether our lithium battery solutions (featuring up to 265 Wh/kg density and 2,000+ cycles) would deliver superior long-term value. Contact us today for application-specific performance analysis and customized battery procurement specifications.