Battery electrolytes are crucial yet often overlooked components in rechargeable batteries. They enable the movement of ions between electrodes, thereby converting chemical energy into electrical power. This process is what powers everything from portable electronics to large-scale energy storage systems, making electrolyte quality a determining factor in battery performance and longevity. Engineers, product developers, and procurement specialists often focus on the cell chemistry, but understanding the role of the electrolyte can guide more informed choices for cost-effective Và reliable battery solutions. At Vade Battery, we prioritize safe, high-performance electrolytes in our custom packs, ensuring our clients benefit from robust Và efficient energy storage.

What Is Battery Electrolyte?

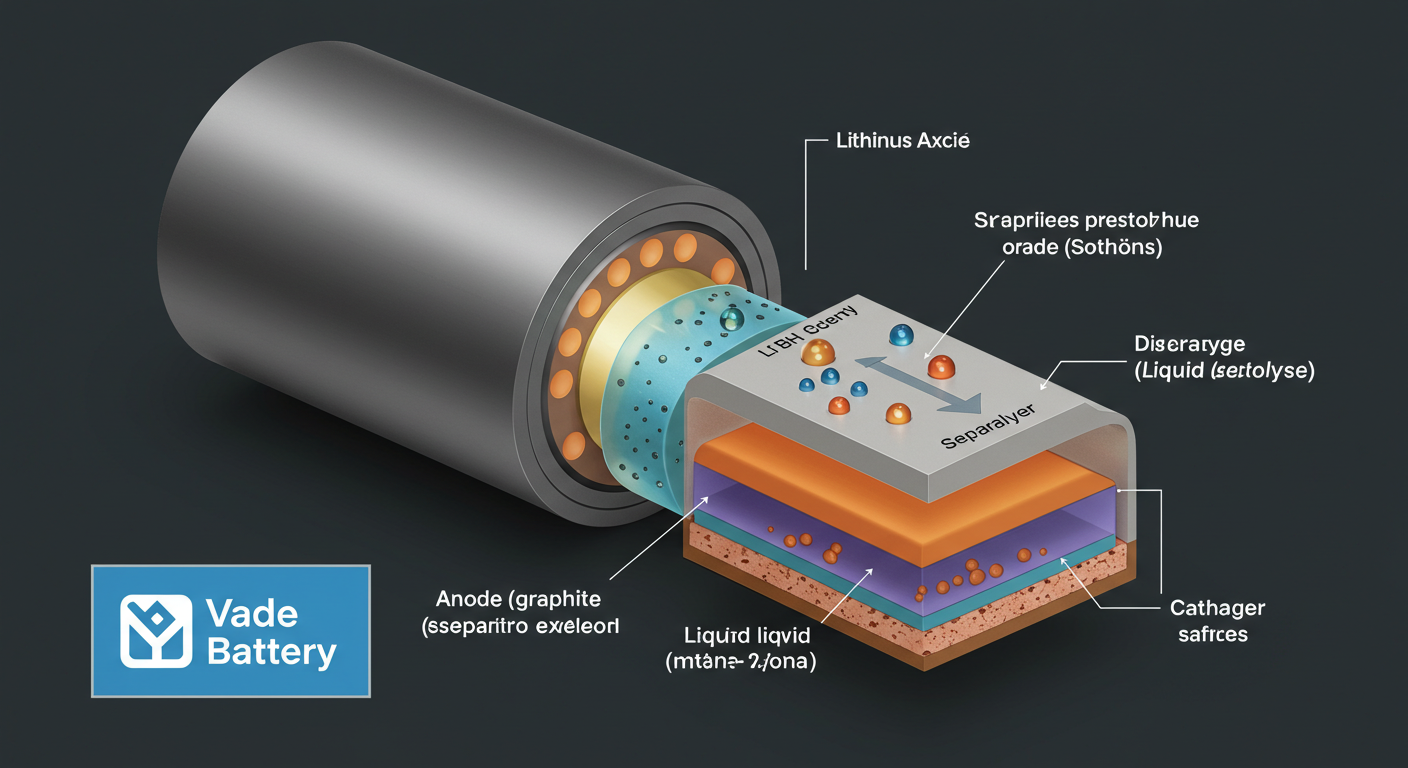

A battery electrolyte is the medium that transports positively charged ions between a battery’s two electrodes, enabling charge and discharge cycles. This solution can be an acid, salt, or base, depending on the battery chemistry, and it can exist in liquid, gel, or even solid form. In a lead-acid battery, the electrolyte is typically sulfuric acid diluted in water, whereas lithium-ion cells use lithium salts dissolved in organic solvents. Although the exact composition varies, the purpose remains the same: to provide an ionic pathway without allowing electrons to flow internally, which prevents short-circuits. By fine-tuning electrolyte properties—like viscosity, conductivity, and chemical stability—battery makers can achieve superior output Và longer cycle life for specialized applications.

How Does Battery Electrolyte Work?

During discharge, ions flow from the anode to the cathode through the electrolyte while electrons travel through the external circuit to power connected devices. When charging, the process reverses, and ions migrate back to the anode. The efficiency of this ion movement depends heavily on electrolyte conductivity and stability under different temperatures. A high-quality electrolyte minimizes internal resistance, which helps maintain the battery’s voltage under load. If the electrolyte is poorly formulated or degraded, voltage drop becomes more pronounced, and heat generation escalates, reducing overall battery lifespan. Effective battery management also relies on the electrolyte’s compatibility with advanced safety features like Battery Management Systems (BMS), which monitor factors such as temperature and voltage, ensuring the electrolyte remains within safe operating conditions.

What Is Battery Electrolyte Made Of?

The composition of a battery electrolyte largely depends on the battery’s underlying chemistry and design requirements. Lead-acid batteries use a solution of water and sulfuric acid, which actively participates in the electrochemical reactions. Alkaline batteries, such as those in common household devices, rely on potassium hydroxide to promote ion flow. In contrast, lithium-ion systems use lithium salts like lithium hexafluorophosphate (LiPF₆) dissolved in organic solvents. These solvents must be stable over a wide voltage range and temperature spectrum, ensuring that ions can shuttle back and forth without degrading the electrodes. Gel and solid-state electrolytes are increasingly researched for their safety benefits, as they reduce the risks of leakage or combustion. By carefully selecting and testing electrolyte formulations, Pin Vade ensures that each custom battery pack meets rigorous hiệu suất Và sự an toàn targets across demanding applications.

Can You Add Electrolyte To a Battery?

Replenishing electrolyte depends on the battery type. Traditional flooded lead-acid batteries often require water to be added periodically because water naturally evaporates or breaks down during charging. In these systems, the acid itself remains in the battery, so only distilled water is introduced. Sealed or maintenance-free batteries, however, are engineered to retain their electrolyte. Such designs, including absorbed glass mat (AGM) and lithium-ion batteries, do not allow for user intervention in electrolyte levels. Attempting to open these sealed units can damage internal components and compromise safety. At Vade Battery, we design our custom lithium-ion packs to be không cần bảo trì, relying on stable electrolyte formulations and robust sealing that eliminate the need for users to add water or chemicals.

What Are the Ingredients in Lithium Battery Electrolytes?

Most lithium-ion electrolytes feature a lithium salt—commonly LiPF₆—dissolved in a blend of organic carbonate solvents like ethylene carbonate or dimethyl carbonate. These mixtures are fine-tuned with additives to improve charge retention, reduce internal resistance, and protect electrode surfaces. LiPF₆ is favored for its balanced ionic conductivity and stable interaction with various electrode materials. Meanwhile, emerging solid-state and polymer-based electrolytes aim to replace flammable organic solvents with safer solid compounds, though they must still achieve adequate ion conductivity. If you require higher energy density or enhanced safety protocols for your application, Pin Vade can custom-engineer a lithium-ion battery pack with an electrolyte system optimized to your specific requirements. Learn more about the cells we use by visiting our Pin Li-ion 18650 page to see how we integrate advanced electrolytes in our designs.

Is Lithium Battery Electrolyte Safe?

The flammable nature of organic solvents in lithium-ion electrolytes poses potential risks like nhiệt độ chạy trốn, where the cell temperature escalates until the electrolyte combusts. Modern lithium-ion batteries mitigate these dangers by incorporating safety vents, flame-retardant additives, and carefully monitored BMS circuitry. Overcharging, punctures, or severe overheating can still trigger electrolyte breakdown, but these events are exceedingly rare in well-manufactured batteries. Pin Vade further enhances safety by rigorously testing each custom pack, implementing cell balancing strategies, and using protective casing materials. As solid-state electrolytes evolve, they offer a path to lower flammability and even higher operational stability. Until then, adhering to specified voltage, temperature, and current limits remains the best way to ensure that lithium battery electrolytes operate safely.

Phần kết luận

Electrolytes might be hidden within the casing of every battery, but they dictate how effectively energy is stored and delivered. Each chemistry, whether lead-acid, alkaline, or lithium-based, relies on an appropriate electrolyte to sustain high performance and long-term stability. Engineers and developers who understand electrolyte dynamics can better select the right chemistry for each project, yielding greater power output Và extended lifespans for their products. At Vade Battery, we emphasize electrolyte formulation, integration with BMS technology, and meticulous pack design to ensure each custom solution meets strict hiệu suất Và sự an toàn benchmarks. For more information on our advanced systems, you can explore our Lithium-ion Battery Pack offerings or contact our team directly at serive@vadebattery.com. By leveraging optimized electrolytes and professional battery engineering, you can secure reliable energy for applications ranging from consumer devices to industrial fleets, all underpinned by Vade Battery’s commitment to innovation Và sự an toàn.