Akü Yük Testi Nedir?

Battery load testing is a diagnostic method for evaluating a battery’s ability to deliver power under real-world operating conditions. It involves applying a controlled electrical load to the battery and observing how the battery’s voltaj ve akım çıkışı respond. In essence, the test simulates the demands of actual usage – such as starting a car engine or powering a device – and checks whether the battery can maintain an adequate voltage when under load. This is a more stringent test than a simple open-circuit voltage check, since a battery can appear fully charged at rest but yük altında beklenen çalışma süresini sağlayamadı. By performing a load test, engineers and technicians can measure key performance indicators like the voltage drop and internal resistance (which reflects the battery’s capability to supply current). These indicators reveal the true health of the battery and help identify weak or aging batteries before they lead to failure in the field.

Akü yük testi, akü güvenilirliğinin kritik olduğu endüstrilerde yaygın olarak kullanılır. Otomotiv mekanikleri, motor çalıştırma için yeterli akım sağlayabildiklerinden emin olmak için araç akülerini (özellikle soğuk krank senaryolarında) yük testine tabi tutar. Yenilenebilir enerji depolama ve yedek güç sistemlerinde, yük testi akü gruplarının elektrik kesintisi sırasında kritik yükleri destekleyeceğini doğrular. Üreticiler of batteries and devices also use load tests for quality control – to verify that new battery packs meet their specifications for capacity and output. In consumer electronics and industrial power systems, routine load testing helps catch performance issues early, preventing unexpected downtime or data loss due to a dying battery.

Akü Yük Testi Neden Önemlidir?

Pil yük testi, pil bakımı, güvenliği ve performans güvencesinde hayati bir rol oynar. Bazı önemli nedenler şunlardır:

- Kalite Kontrol (Üreticiler): Üretim sırasında yük testleri uygulamak, pillerin tasarım özelliklerini ve kalite standartlarını karşılamasını sağlar. Üretim hatalarını veya hücre dengesizliklerini erken tespit etmeye yardımcı olur ve düşük kaliteli pillerin pazara ulaşmasını önler. Bu, genel ürün güvenilirliğini artırır ve garanti taleplerini azaltır.

- Son Kullanıcılar İçin Güvenilirlik: For businesses and individuals who rely on batteries, load testing is crucial to verify that a battery will perform when it’s needed most. For example, backup power systems in telecom or data centers are routinely load-tested to validate battery capacity and runtime. This process can uncover weak cells or wiring issues önce they cause unplanned downtime. By identifying a declining battery in an electric vehicle, solar storage bank, or UPS system, it can be replaced proactively – avoiding sudden failures and ensuring continuous operation.

- Performans Optimizasyonu ve Ömür: Regular load testing helps in tracking a battery’s available capacity and internal resistance over time. By comparing test results against the battery’s rated capacity, users can determine when the battery has aged significantly. This information allows for optimized charging schedules and timely maintenance. Keeping batteries “exercise tested” under load can also prevent capacity loss from long periods of inactivity, thereby extending their usable lifespan.

- Güvenlik ve Uyumluluk: Faulty or deteriorating batteries can pose safety risks such as overheating, leakage, or in extreme cases (particularly with lithium-ion chemistries) thermal runaway. Load testing under controlled conditions can reveal these issues early, so that unsafe batteries are removed from service. Moreover, many industry standards and transportation regulations require rigorous battery testing. For instance, virtually all lithium-ion batteries must pass the UN 38.3 safety tests – a series of abuse and load conditions – to be certified for transport. Systematically load-testing battery systems helps ensure compliance with such standards and gives confidence that batteries can withstand the stresses of actual use.

Pil Yük Testi Prensipleri

Temel olarak, pil yük testi basit bir prensiple çalışır: apply a known load and measure the battery’s response. By observing how much the voltage drops under load and how well the battery sustains the load current, one can infer the battery’s internal condition. A healthy battery will maintain a higher voltage and recover quickly after the test, whereas a weak battery’s voltage will sag significantly under load and may struggle to recover afterward. The amount of voltage drop is directly related to the battery’s internal resistance – lower internal resistance means the battery can deliver higher current with less voltage drop.

Bir yük testi sırasında çeşitli parametreler yakından izlenir: gerilim düşüşü yük uygulandığında akü boyunca, akım flowing, and often the battery’s sıcaklık test sırasında. Önemli voltaj düşüşü veya anormal ısı üretimi, artan iç direnci veya hücre hasarını gösterebilir. Buna karşılık, iyi durumda olan bir pil, belirtilen yük için yalnızca mütevazı bir voltaj düşüşü ve az ısınma gösterecektir.

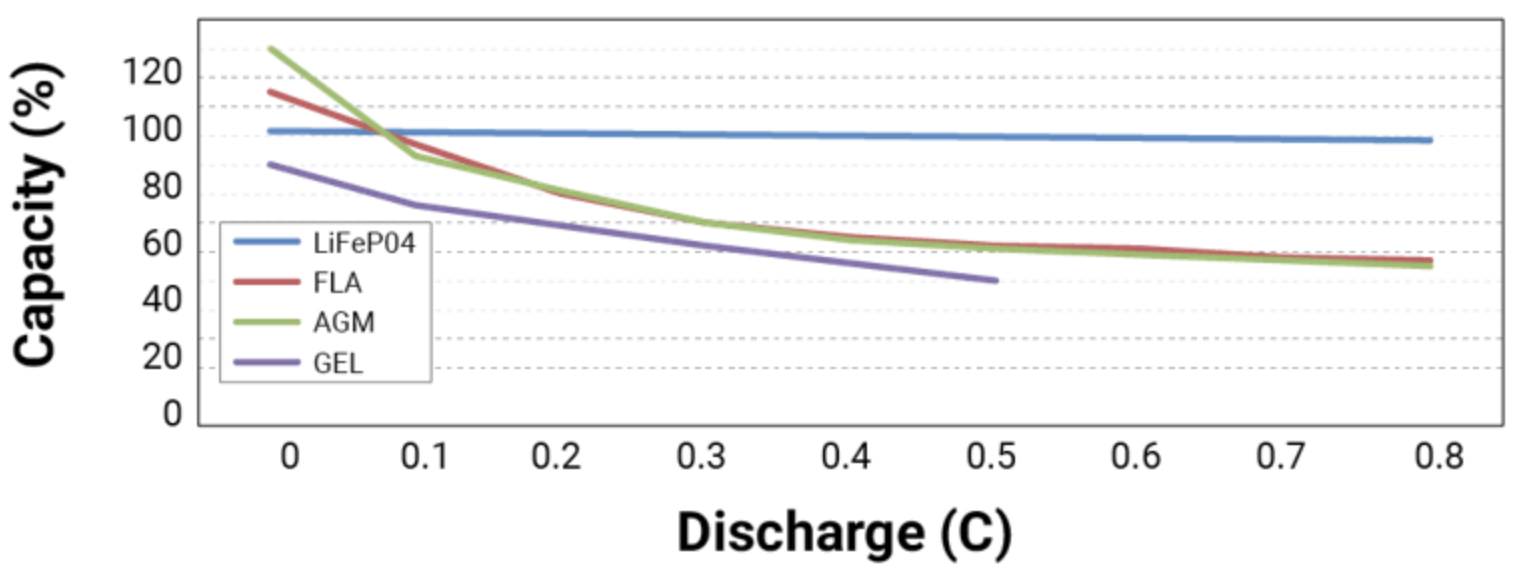

Bir akünün yük altındaki davranışı aynı zamanda kimyasına ve tasarımına da bağlıdır. Farklı akü tiplerinin farklı deşarj özellikleri vardır. Örneğin, kurşun-asit aküler yüksek deşarj oranlarında daha büyük bir voltaj düşüşü ve etkili kapasite kaybı gösterme eğilimindeyken, lityum-iyon aküler (özellikle Lityum Demir Fosfat, LiFePO4) daha kararlı bir voltaj korur ve ağır yükler altında bile kapasitelerinin daha yüksek bir yüzdesini sunar. Bu, bir lityum akünün genellikle eşdeğer olarak derecelendirilmiş bir kurşun-asit aküden daha iyi yüksek akım çekimlerini idare edeceği anlamına gelir.

Bu kimya farklılıklarını anlamak, yük testi sonuçlarını yorumlarken önemlidir. Bir pil türü için normal olabilecek bir voltaj düşüşü, başka bir pil türünde bir soruna işaret edebilir. Benzer şekilde, bir hafif Yoğun olarak kullanılan bir kurşun-asit akü için zaman içinde kapasitede düşüş beklenebilir, ancak iyi yönetilen bir Li-ion paketi aynı sayıda döngü boyunca kapasitesinin çoğunu koruyabilir.

Sıcaklık is another critical factor influencing load testing. Batteries perform best around room temperature, and both cold and hot conditions can skew test outcomes. In cold environments, a battery’s internal resistance increases and its ability to deliver current decreases – effectively reducing its available capacity. For instance, a battery that provides full capacity at about 27 °C (80 °F) might only deliver roughly 50% of its capacity at –18 °C (0 °F). Importantly, this capacity loss in the cold is usually geçici: Pil normal sıcaklıklara geri döndüğünde, performansı genellikle önceki seviyelere geri döner. Because of this, load tests are usually conducted at standardized temperatures (around 20–25 °C, unless the goal is to specifically test cold/hot performance) to ensure the results reflect the battery’s true health rather than a transient thermal effect.

Doğru ve anlamlı veriler elde etmek için, yük testi bir dizi en iyi uygulamayı takip eder. Piller genellikle tam şarj olduğunda test edildi and in a rested state (no recent charging or discharging that could skew the voltage). The load applied should be chosen to mimic the battery’s real-world application – for example, drawing a high burst current to simulate a power tool or vehicle starter, or a steady lower current to simulate a device drain. The test is run for a defined duration long enough to observe the battery’s behavior (but usually short enough to avoid completely depleting the battery or causing undue stress). Throughout the test, conditions are kept controlled: the ambient temperature is kept stable, and the test equipment (load banks, meters, etc.) is kalibre edilmiş for accuracy. Following these principles ensures that the load test results can be reliably compared to manufacturer specifications and previous test results, giving a clear picture of the battery’s state of health.

Pil Yük Testi Türleri

Her biri farklı amaçlara ve pil sistemlerine uygun çeşitli pil yük testi türleri vardır:

- Sabit Akım Yük Testi: A steady, fixed current is drawn from the battery for a specified period. By measuring how the battery’s voltage declines over time under this constant load, one can assess its capacity and voltage stability. This is a common method to determine a battery’s true amp-hour capacity – for example, discharging at a 1 C rate (equal to the battery’s rated capacity) and seeing how long it sustains the load before reaching a cutoff voltage.

- Darbe Yük Testi: The battery is subjected to intermittent high-current pulses separated by rest periods. This tests the battery’s response to sudden power demands. The voltage is monitored during each pulse to see how well it recovers in the brief rest. Pulse testing is often used to evaluate starting batteries or batteries in devices that periodically draw bursts of current. It can also help estimate internal resistance and dynamic performance without fully discharging the battery.

- Kapasite (Çalışma Zamanı) Testi: Bu esasen kontrollü tam deşarj testidir. Pil, kesme noktasına (minimum güvenli voltaj) ulaşana kadar belirli bir oranda (sabit akım veya simüle edilmiş kullanım modeli olabilir) deşarj edilir. Verilen toplam süre veya toplam enerji ölçülür. Bu, kullanılabilir kapasite pilin ve bu koşullar altında çalışma süresinin doğrudan bir ölçümünü sağlar. Bu tür testler, bir pilin hala beklenen şarjı tutup tutmadığını kontrol etmek için yararlıdır. Örneğin, bir UPS pil dizisi, voltaj çok düşmeden önce yükü gereken süre boyunca (örneğin 30 dakika) destekleyebildiğinden emin olmak için deşarj testine tabi tutulabilir.

- Krank Yükleme Testi: Used primarily for automotive and lead–acid starter batteries, this test measures the battery’s ability to deliver a very high current for a short duration (as needed to crank an engine). A specialized load tester or carbon pile applies a heavy load (hundreds of amps for a car battery) for 5–10 seconds while monitoring the voltage. The voltage should stay above a specified threshold (e.g. ~9.6 V for a 12 V battery at room temperature, higher if tested warm) during the crank simulation. A battery that cannot maintain voltage under this brief but intense load is likely failing, even if it reads 12 V in open-circuit. Cranking tests are often part of car battery diagnostics, especially in cold weather, to ensure reliable starts.

Pil Yük Test Ekipmanları

Bir yük testini güvenli ve doğru bir şekilde gerçekleştirmek doğru ekipmanı gerektirir. Temel araçlar ve bileşenler şunlardır:

- Yük Test Cihazı / Yük Bankası: This is the device that actually puts a controlled load on the battery. Simple portable load testers for car batteries use a resistor or carbon pile to draw a high current. More advanced electronic load banks can be programmed to draw specific currents or profiles and often include built-in meters. The load tester typically measures the battery’s voltage under load, and some models also measure internal resistance and other metrics.

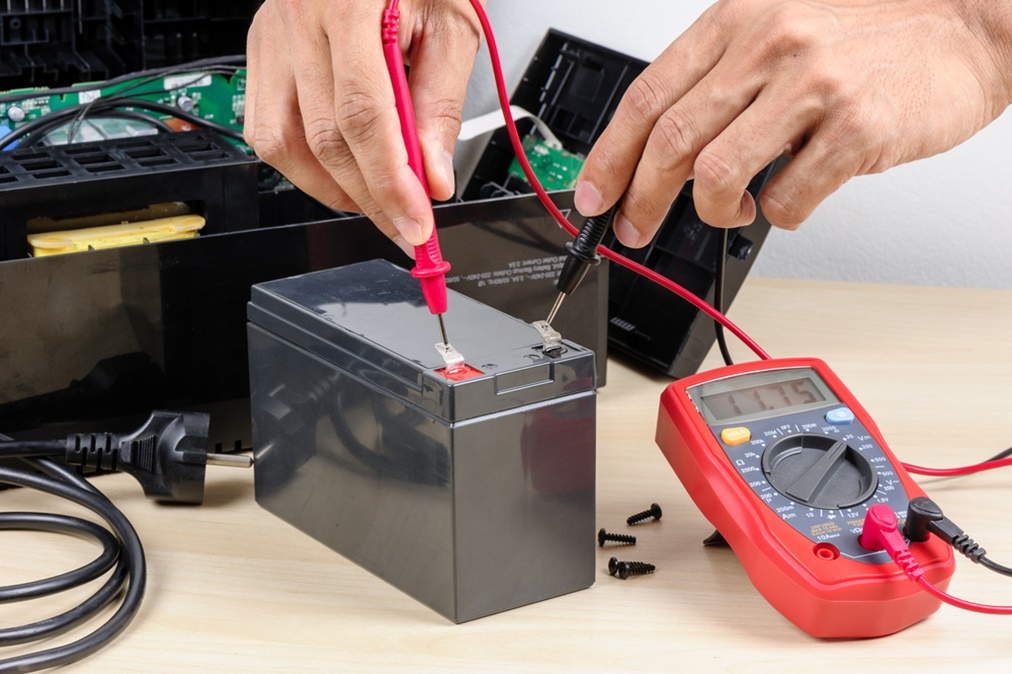

- Multimetre veya Voltmetre: A calibrated multimeter is used to independently measure the battery’s voltage and sometimes current during testing. This provides accurate readings and a sanity check against the load tester’s built-in measurements. In some cases, clamp ammeters are also used to verify the exact current being drawn.

- Veri Kaydedici / Pil Analizörü: For more detailed testing (especially in research, manufacturing, or predictive maintenance), data acquisition devices record the battery’s voltage, current, and temperature throughout the load test. The resulting data can be analyzed to see how quickly the voltage declines, how stable the current draw remained, and if there were any irregular drops or recoveries. This is useful for comparing multiple batteries or tracking a battery’s performance over time.

- Sıcaklık Sensörü: Because temperature greatly affects battery behavior, testers often monitor ambient and battery temperature. In critical testing, thermocouples might be attached to the battery to ensure it’s within the desired temperature range and to detect any dangerous overheating during the test.

- Güvenlik Ekipmanları: Yük testi bir aküyü zorlayabilir, bu nedenle güvenlik en önemli unsurdur. Özellikle bir şeyler ters giderse kıvılcım veya elektrolit yayabilecek daha büyük akülerde yalıtımlı eldivenler ve göz koruması gibi koruyucu donanımlar giyilmelidir. Kurşun-asit aküleri (hidrojen gazı yayabilir) test ederken uygun havalandırma gerekir ve yüksek enerjili lityum aküleri test ederken yangın söndürme araçları el altında olmalıdır. Ek olarak, yük için doğru dereceli kablolar ve kelepçeler kullanmak, yüksek akım testleri sırasında aşırı ısınmalarını önlemek için önemlidir.

Pil Yük Testi Süreci

When you are ready to conduct a battery load test, it’s important to follow a structured process:

- Hazırlık: Begin with a fully charged battery. Make sure the battery has been rested for a while after charging so that the voltage has stabilized (surface charge dissipated). Check the ambient conditions – ideally, test in a room-temperature environment unless you are specifically evaluating cold or hot performance. Gather all required equipment (load tester, multimeter, etc.), and put on appropriate safety gear. Also, review the battery’s specifications to know what load and voltage values to expect (for example, maximum test current or minimum allowable voltage).

- Ekipmanı Bağlayın: Turn off or set the load tester to zero before connecting. Attach the load tester’s leads to the battery terminals: positive (+) to positive, negative (–) to negative, ensuring solid connections. If using a separate voltmeter or data logger, connect those probes or sensors to the battery as well. Double-check all connections are secure to avoid arcing when the test begins.

- Yükleme Parametrelerini Ayarlayın: Configure the load tester to the desired load. This could mean dialing in a certain current (e.g. a 50 A draw for a small battery, or a 300 A draw for a car battery test), or selecting a specific test mode on an electronic load (constant current, pulse, etc.). Refer to the battery’s ratings or the relevant standard for guidance – for instance, use a load equal to half the battery’s CCA rating for an automotive load test, or a 0.2 C (5-hour rate) load for a capacity test, depending on the goal.

- Testi Gerçekleştirin: Yük test cihazını etkinleştirerek aküden akım çekmeye başlayın. Yükü belirtilen süre boyunca uygulayın. Bu, yüksek akım testi için sadece birkaç saniye veya uzun süreli deşarj testi için dakikalar veya saatler olabilir (bu durumda yükün sabit kaldığından emin olun veya gerekli profili izleyin). Monitor the battery’s behavior throughout. Observe the voltage reading – a sharp drop initially is normal, but it should stabilize above the minimum acceptable voltage. Watch for any signs of distress such as the battery overheating, smoking, or emitting unusual odors (if so, terminate the test immediately). If using a data logger, ensure it’s recording properly.

- Sonuçları İzleyin ve Analiz Edin: Once the test interval is completed, remove or turn off the load. Continue to watch the battery’s voltage recovery for a minute or two. Note the loaded voltage and the recovery voltage. Now analyze the data: Did the battery maintain voltage above the cutoff threshold during the test? How much capacity (Ah or minutes of runtime) was delivered in a full discharge test? Compare these outcomes to the battery’s rated specifications or to previous test results. A healthy battery should meet or come close to its specs (e.g. delivering its rated amp-hours, or keeping above the minimum voltage under load). If the battery’s performance falls short, it may indicate aging or damage. Use this information to decide on next steps – for example, keep the battery in service with a scheduled re-test later, or retire/replace the battery if it failed to perform.

Yük Testi Sonuçlarının Yorumlanması

Bir akü yük testinin sonucunu anlamak, testin kendisini gerçekleştirmek kadar önemlidir. Sonuçları yorumlarken dikkate alınması gereken temel hususlar şunlardır:

- Gerilim Tepkisi: Observe how the battery’s voltage behaved under load. A kararlı voltaj that stays within expected limits indicates a healthy battery with low internal resistance. If the voltage dropped significantly (below the recommended cutoff for that battery type), that’s a red flag. For instance, if a 12 V battery falls well below ~10 V under a moderate load, it likely cannot supply the required current or has substantially lost capacity. Also, note the recovery voltage after the load is removed – a healthy battery’s voltage will bounce back close to its normal resting value, whereas a weak battery may recover only partially or very slowly.

- Kapasite ve Çalışma Süresi: Yük testi zamanlanmış bir deşarj ise (örneğin sabit akımda 2 saatlik bir test), etkin kapasiteyi hesaplamak için verileri kullanın. ölçülen kapasite (or runtime) to the battery’s rated capacity. A significantly lower capacity (e.g. a battery rated for 100 Ah only delivered 60 Ah before hitting cutoff) suggests the battery has aged or deteriorated. Many organizations use an 80% rule of thumb – if a rechargeable battery’s tested capacity falls below ~80% of its original rating, the battery is considered at end-of-life and should be replaced to ensure reliability.

- İç Direnç ve Gerilim Düşümü: From the voltage and current data, you can infer the battery’s internal resistance (Ohm’s law: ΔV = I * R_internal). An increasing internal resistance over successive tests is a sign of aging. High internal resistance will cause excessive voltage drop even at moderate loads, leading to poor performance. Some battery testers measure this directly. If you see that even small loads cause a notable voltage dip, the battery likely has a high internal impedance and may fail under heavier loads.

- Sıcaklık ve Diğer Anomaliler: If you recorded temperature, assess whether the battery was heating significantly under load. A rise in temperature during a short test can indicate inefficiencies (energy lost as heat due to internal resistance) or internal cell damage. Any signs of swelling, venting, or leakage observed during or after the test are indicators of a failing battery and a serious reason to remove it from service. In a properly functioning battery, temperature should remain within normal limits for the test’s duration (most of the battery’s energy should be going into the load, not heating the battery itself).

- Zaman İçindeki Trendler: One load test provides a snapshot, but multiple tests over a battery’s life can illustrate trends. Keep records of each battery’s test results. If you notice, for example, that each quarterly test shows the voltage under load dropping lower than the last time, or the delivered capacity decreasing gradually, you have a quantified record of the battery’s degradation. This trend analysis allows for predictive maintenance – you can plan to replace batteries önce tamamen başarısız olurlar. Büyük pil kurulumlarında (veri merkezi UPS sistemleri veya güneş depolama bankaları gibi), her bir ünite için bu eğilimlerin izlenmesi, zayıf üniteleri zamanında değiştirerek tüm pil bankasının güvenilir kalmasını sağlamaya yardımcı olur.

By combining all these observations, you can make an informed judgment about the battery’s health. A good outcome (voltage stable, capacity on target, no excessive heat) means the battery is fit for continued use. Any poor results should prompt further action – perhaps recondition or balance the battery if possible, or retire the battery and replace it to maintain system reliability. Remember that güvenlik önce gelir: if a battery shows severe problems (can’t hold voltage, overheats, etc.), remove it from service, as those issues can escalate to complete failure or safety hazards under continued use.

Çözüm

Battery load testing is an essential practice for anyone who depends on reliable battery power. By applying realistic loads and scrutinizing how a battery performs, this test provides invaluable insight into the battery’s true state of health that simple voltage readings can’t offer. Regular load testing helps manufacturers ensure product quality and helps users avoid unexpected battery failures by catching early warning signs of degradation. In applications ranging from automobiles to backup power systems, load testing underpins both performans optimizasyonu ve güvenlik, verifying that each battery can meet the demands placed on it. By understanding and implementing proper load testing – following the principles, using the right equipment, and interpreting the results wisely – one can extend battery life, plan timely maintenance, and ensure that critical battery-powered systems remain up and running when they’re needed most.