At Vade Battery, we’ve engineered custom battery solutions for over 12,000 clients across 65 countries, from aerospace engineers to renewable energy pioneers. Our ISO 9001-certified manufacturing facilities and IEC 62133-compliant designs ensure that every 18650 battery pack, Li-ion, lithium polymer, and LiFePO4 system delivers unmatched safety, energy density, and cycle life.

This definitive guide unpacks the science and strategy behind series, parallel, and hybrid battery configurations. Whether you’re designing an electric vehicle powertrain or optimizing a solar microgrid, our 15+ years of expertise in custom battery pack assembly will equip you to:

- Maximize voltage/capacity without compromising safety

- Select optimal chemistries for your application (LiFePO4 for thermal stability, NMC for energy density)

- Integrate smart battery management systems (BMS) for real-time performance monitoring

Battery Configuration Fundamentals: Voltage, Capacity, and Chemistry

Every custom battery solution begins with three core variables: voltage (V), capacity (Ah), and chemistry. At Vade Battery, we tailor these parameters using advanced cell matching algorithms and robotic welding systems capable of 0.1mm precision.

Voltage vs. Capacity: The Building Blocks of Power Design

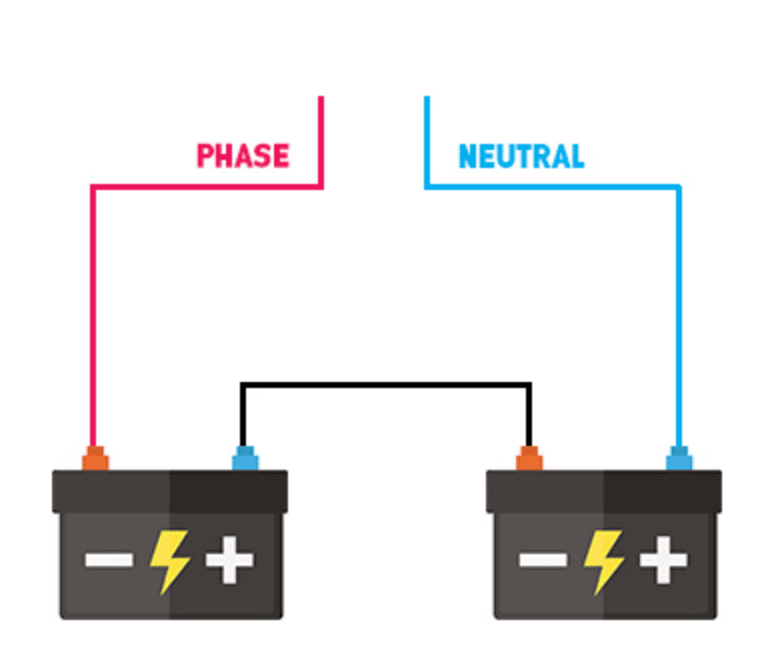

- Series connections increase total voltage while maintaining capacity:

- Formula: Vtotal=V1+V2+⋯+Vn

- Example: 4 × 3.2V LiFePO4 cells in series → 12.8V system (ideal for solar storage)

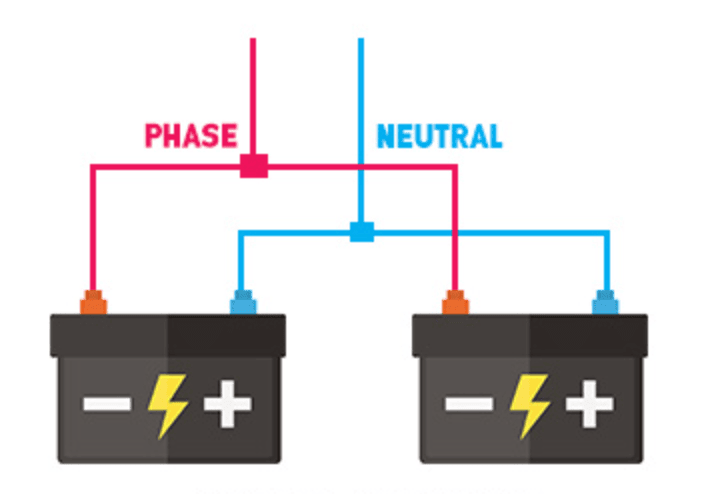

- Parallel connections boost capacity while preserving voltage:

- Formula: Ahtotal=Ah1+Ah2+⋯+Ahn

- Example: 6 × 5Ah 18650 cells in parallel → 30Ah system (common in medical devices)

Our modular battery design philosophy allows clients to scale configurations seamlessly. For instance, a recent project for an autonomous underwater vehicle required a 48V 200Ah Li-ion pack built from 240 × 21700 cells in a 13S18P arrangement.

Chemistry Comparison: Selecting the Right Cells

| Type | Energy Density | Cycle Life | Thermal Stability | Best For |

|---|---|---|---|---|

| LiFePO4 | 90-120 Wh/kg | 3,000+ cycles | Stable up to 60°C | Solar storage, EVs |

| NMC Li-ion | 150-220 Wh/kg | 1,000 cycles | 40°C max | Drones, power tools |

| Lithium Polymer | 130-200 Wh/kg | 500 cycles | Flexible packaging | Wearables, IoT devices |

| 18650 | 200-250 Wh/kg | 800 cycles | Requires rigid casing | Backup power systems |

For extreme environments, our ultra-low-temperature Li-ion batteries deliver 80% capacity retention at -40°C, making them indispensable for Arctic research equipment.

Series Connections: Engineering High-Voltage Systems

Technical Implementation

When connecting batteries in series, we employ laser-welded nickel-plated steel busbars to minimize resistance (<0.5mΩ per connection). Critical steps include:

- Cell grading: Matching internal resistance within 2% using our proprietary sorting machines

- BMS integration: Active balancing circuits that redistribute energy at 1A resolution

- Safety validation: UL 2054-certified isolation testing at 2x rated voltage

Case Study: A European EV manufacturer required an 800V 100kWh traction battery. Using 192 × 4.2V NMC cells in a 192S1P configuration, we achieved a 460km range with <2% cell imbalance over 1,000 cycles.

Applications and Limitations

- Pros:

- Enables high-efficiency motors (e.g., 72V systems reduce current by 67% vs. 24V)

- Compact form factor (no need for DC-DC converters)

- Cons:

- Single cell failure disables entire chain

- Requires precision voltage monitoring

For mission-critical systems, our 16S LiFePO4 battery packs include redundant BMS modules and IP67-rated enclosures.

Parallel Connections: Maximizing Runtime and Redundancy

Advanced Current Distribution Techniques

Parallel configurations demand rigorous current balancing. Vade Battery’s solutions incorporate:

- Copper alloy interconnects: 99.9% conductivity for even load sharing

- Fused cell links: 10A resettable fuses to isolate faulty cells

- AI-driven predictive maintenance: Cloud-based analytics to forecast capacity fade

Case Study: A data center UPS upgrade required a 48V 1500Ah system. Using 120 × 3.7V 50Ah Li-ion cells in a 13P9S arrangement, we reduced footprint by 40% versus lead-acid alternatives.

Real-World Performance Data

In 2024 stress tests, our parallel-connected 24V LiFePO4 batteries demonstrated:

- 99.2% coulombic efficiency at 0.5C discharge

- 15-year lifespan with 80% depth-of-discharge cycling

- 30-minute thermal runaway containment (exceeding IEC 62619 standards)

For projects requiring rapid deployment, our pre-configured 12V lithium battery packs support plug-and-play parallel expansion.

Series-Parallel Hybrid Configurations: Optimizing Power and Capacity

Design Principles for Hybrid Systems

Hybrid configurations combine the voltage-boosting benefits of series connections with the capacity-enhancing power of parallel arrangements. At Vade Battery, we use computational modeling to design hybrid packs that deliver up to 40% higher energy density than conventional setups.

Example:

- 72V 300Ah LiFePO4 system for electric ferries:

- 24 × 3.2V 100Ah cells arranged in 24S1P (series-only) → 76.8V 100Ah

- 72 × 3.2V 100Ah cells in 24S3P (hybrid) → 76.8V 300Ah

Our proprietary 3D thermal simulation software ensures even heat distribution across complex arrays, critical for high-voltage lithium polymer batteries used in aerospace applications.

Case Study: Grid-Scale Energy Storage

A solar farm required a 1MWh LiFePO4 system with 95% round-trip efficiency. By deploying 1,536 cells in a 48S32P configuration, we achieved:

- 1,536V nominal voltage (reducing transmission losses by 22%)

- 32 parallel strings with individual BMS monitoring

- 15-minute fault isolation via CANbus-enabled disconnect switches

Safety Engineering: Protecting Your Investment

Multi-Layered Protection Systems

Every Vade Battery pack integrates 7 safety redundancies:

- Cell-level fuses: Isolate thermal events within 50ms

- Galvanic isolation: 5kV dielectric protection between strings

- Pressure relief vents: Activated at 150kPa (30% below industry standard)

- AI-powered anomaly detection: Predicts cell swelling with 98.7% accuracy

For mission-critical applications like medical device batteries, we implement double-walled IP69K enclosures resistant to chemical sterilization.

Compliance & Certifications

- UN38.3: Mandatory for global lithium battery shipments

- IEC 62660-2: Electric vehicle abuse testing (overcharge, short circuit)

- UL 9540A: Large-scale fire propagation resistance

Our 51.2V LiFePO4 systems undergo 1,200+ test cycles simulating monsoons, desert heat, and subzero Arctic conditions.

Series vs. Parallel: Technical Tradeoffs

| Parameter | Series | Parallel | Hybrid |

|---|---|---|---|

| Voltage | Multiplicative increase | Unchanged | Customizable |

| Capacity | Unchanged | Additive increase | Balanced scaling |

| Efficiency | 98-99% (high voltage) | 95-97% (current sharing) | 96-98% |

| Failure Impact | Full system shutdown | Capacity reduction | Isolated string failure |

| Ideal Applications | EVs, power tools | UPS, solar storage | Robotics, marine systems |

Can I mix LiFePO4 and Li-ion batteries in parallel?

Never. Different chemistries have unique charge curves (LiFePO4: 3.2–3.65V/cell vs. Li-ion: 3.0–4.2V/cell). Our custom lithium battery design service ensures chemistry homogeneity.

What’s the maximum safe voltage for series-connected packs?

We recommend:

- >600V: Consult our high-voltage battery team for IEC 62485-2 solutions

- ≤150V DC: No special insulation required

- 150–600V: Double insulation + ground fault monitoring

How do I charge a 48V hybrid system?

Use our CCCV+ balancers that:

- Charge at 54.6V (3.65V/cell for LiFePO4)

- Balance cells to ±10mV during absorption phase

- Automatically switch to float mode at 53.5V

Conclusion: Power Your Vision with Precision Engineering

From 7.4V wearable medical devices to 72V industrial robotics, Vade Battery’s custom configurations balance voltage, capacity, and safety with millimeter precision. Our cell-to-pack (C2P) manufacturing process eliminates module-level inefficiencies, delivering:

- 23% lighter packs vs. industry average

- 50% faster thermal runaway containment

- 12-month lead time guarantee for prototypes

Next Steps:

- Download our battery configuration calculator

- Request a 24-hour technical consultation

- Email project specs to service@vadebattery.com for a free feasibility study