-

29 W. Pawnee, Bloomfield, NJ 07003

Lithium Ion Battery VS Nickel Cadmium Battery: Which Battery is Better?

When choosing between a lithium-ion battery and a nickel-cadmium battery, understanding their fundamental differences is crucial for making an informed decision. As we move through 2025, battery technology continues to evolve, but these two established chemistries still dominate many applications due to their distinct characteristics. I’ll guide you through a comprehensive comparison to help you determine which battery type best suits your specific needs.

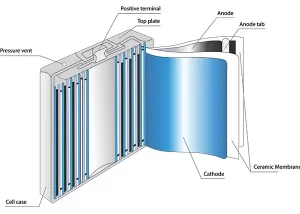

What is a Lithium-Ion Battery?

A lithium-ion battery is a rechargeable energy storage device that has revolutionized portable electronics since its commercial introduction in the early 1990s. These batteries utilize lithium ions as the primary component for their electrochemical reactions, moving between the anode and cathode during charge and discharge cycles.

The fundamental components of a lithium-ion battery include:

- Positive electrode (cathode): Typically made of lithium cobalt oxide (LiCoO₂), lithium nickel manganese cobalt oxide (LiNiMnCoO₂), or lithium iron phosphate (LiFePO₄)

- Negative electrode (anode): Usually composed of graphite

- Electrolyte: A lithium salt in an organic solvent that facilitates ion movement

- Separator: A microperforated film that prevents direct contact between electrodes while allowing ions to pass

During the charging process, lithium ions move from the cathode to the anode through the electrolyte, creating a potential difference. When discharging, this process reverses as ions travel back to the cathode, generating electrical energy that powers your devices. This efficient ion movement mechanism gives lithium-ion batteries their impressive performance characteristics and has made them the preferred choice for numerous applications.

Advantages of Lithium-Ion Batteries

Lithium-ion batteries offer several significant advantages that have contributed to their widespread adoption across multiple industries and applications:

High Energy Density: Lithium-ion batteries can store substantially more energy per unit of weight and volume compared to other rechargeable batteries. This superior energy density makes them ideal for portable devices and applications where space and weight considerations are critical.

Lightweight Construction: The lightweight nature of lithium-ion batteries contributes significantly to their popularity in mobile devices, electric vehicles, and aerospace applications. Their high power-to-weight ratio provides longer runtime without adding excessive weight to the devices they power.

No Memory Effect: Unlike nickel-cadmium batteries, lithium-ion batteries do not suffer from the “memory effect,” which can reduce a battery’s capacity over time. This means you can charge a lithium-ion battery at any point in its discharge cycle without negatively affecting its long-term capacity.

Fast Charging Capabilities: Lithium-ion batteries can accept charge at a much faster rate than many alternative technologies. This quick-charging ability minimizes downtime and ensures your devices remain operational when you need them most.

Low Self-Discharge Rate: When not in use, lithium-ion batteries retain their charge exceptionally well, typically losing only 1-2% per month. This low self-discharge rate ensures they remain ready for use even after extended periods of inactivity.

Minimal Maintenance Requirements: These batteries do not require scheduled cycling or other regular maintenance procedures to maintain their performance level. This convenience factor, combined with their other benefits, has contributed significantly to their widespread adoption.

Limitations of Lithium-Ion Batteries

Despite their numerous advantages, lithium-ion batteries come with certain limitations that should be considered when evaluating their suitability for specific applications:

Limited Lifespan: Lithium-ion batteries typically have a finite lifespan of approximately 2-3 years or 300-500 full charge cycles before noticeable capacity degradation occurs. Even with proper care, you’ll eventually observe a decrease in their ability to hold a charge.

Safety Concerns: Although rare, lithium-ion batteries can experience thermal runaway under certain conditions, potentially leading to fires or explosions. This risk increases if the batteries are damaged, improperly charged, or exposed to extreme temperatures. At VADE Battery, we implement comprehensive safety features and recommend following proper storage guidelines for lithium batteries to minimize these risks.

Temperature Sensitivity: Performance can degrade significantly in extreme temperatures. In very cold conditions, lithium-ion batteries may deliver substantially reduced capacity, while high temperatures can accelerate degradation and potentially create safety hazards.

Higher Cost: Lithium-ion batteries generally carry a higher price tag compared to alternative battery technologies like nickel-cadmium. This cost premium stems from the expense of lithium resources, sophisticated manufacturing processes, and the advanced protection circuitry required for safe operation.

Environmental Considerations: While lithium-ion batteries are generally considered more environmentally friendly than nickel-cadmium batteries, they still raise concerns related to resource extraction (particularly for materials like cobalt and lithium) and end-of-life disposal. Proper recycling infrastructure is essential to mitigate these environmental impacts.

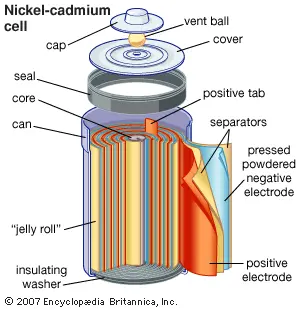

What is a Nickel-Cadmium Battery?

Nickel-cadmium (NiCd) batteries have been a commercial mainstay since 1907, making them one of the oldest rechargeable battery technologies still in widespread use today. These batteries operate through a well-established electrochemical process that has been refined over more than a century of development.

The primary components of a nickel-cadmium battery include:

- Positive electrode (cathode): Made of nickel oxide hydroxide

- Negative electrode (anode): Composed of metallic cadmium

- Electrolyte: Typically potassium hydroxide in an alkaline solution

- Separator: Prevents direct contact between electrodes while allowing ion flow

During charging, the nickel compound undergoes oxidation while the cadmium compound is reduced. During discharge, this chemical reaction reverses, generating electrical current that powers connected devices. This reversible electrochemical reaction between the nickel and cadmium compounds enables the battery to store and release energy efficiently over thousands of cycles.

Advantages of Nickel-Cadmium Batteries

Nickel-cadmium batteries offer several distinct advantages that have contributed to their continued use in specific applications despite the growing popularity of newer battery technologies:

Exceptional Temperature Tolerance: NiCd batteries demonstrate remarkable performance across an extensive temperature range, functioning reliably from -40°C to +70°C (-40°F to +158°F). This exceptional temperature resilience makes them particularly well-suited for applications in harsh environmental conditions where other battery types might fail.

High Discharge Rate Capability: These batteries can deliver very high current outputs, making them ideal for applications requiring sudden bursts of power. This capability has maintained their popularity in power tools, emergency equipment, and aviation applications where reliable power delivery under heavy loads is critical.

Impressive Cycle Life: Properly maintained NiCd batteries can withstand 1,000-2,000 complete charge-discharge cycles before showing significant capacity degradation. This exceptional longevity translates to decades of service in industrial applications with appropriate maintenance regimens.

Low Internal Resistance: NiCd batteries maintain a consistently low internal resistance throughout their discharge cycle, enabling them to deliver stable voltage output even under heavy loads. This characteristic ensures reliable performance in high-drain applications.

Durability and Ruggedness: These batteries exhibit remarkable resistance to physical abuse, electrical abuse (overcharging and over-discharging), and vibrational stress. This robustness makes them particularly valuable in industrial equipment, aviation, and emergency systems where reliability is paramount.

Cost-Effectiveness: NiCd batteries generally have a lower initial purchase price compared to lithium-ion alternatives. When considering their exceptional cycle life and durability, they can offer superior long-term value for appropriate applications despite higher maintenance requirements.

Limitations of Nickel-Cadmium Batteries

Despite their impressive performance characteristics, nickel-cadmium batteries have several significant limitations that have contributed to their declining popularity in many consumer applications:

Memory Effect: Perhaps the most widely known limitation of NiCd batteries is the “memory effect,” where the battery appears to “remember” partial discharge levels if repeatedly recharged without full discharge. While modern NiCd batteries have improved in this regard, the issue can still reduce usable capacity over time if charging patterns are not managed appropriately.

Environmental Toxicity: NiCd batteries contain cadmium, a highly toxic heavy metal that poses significant environmental and health risks. Improper disposal can lead to soil and water contamination, with cadmium potentially entering the food chain. According to research, waste nickel-cadmium batteries account for approximately 92% of the total cadmium in municipal waste.

Regulatory Restrictions: Due to cadmium’s toxicity, many regions have implemented strict regulations limiting the use of NiCd batteries. The European Union’s Battery Directive, for example, has restricted the use of cadmium in batteries since 2006, with exemptions for emergency systems, medical equipment, and some industrial applications.

Lower Energy Density: Compared to lithium-ion batteries, NiCd batteries have substantially lower energy density. This means they require more space and weight to deliver equivalent capacity, making them less suitable for applications where size and weight are critical considerations.

Higher Self-Discharge Rate: NiCd batteries lose their charge more rapidly when not in use compared to lithium-ion alternatives. With a self-discharge rate of approximately 10-20% per month, they require more frequent recharging during periods of inactivity.

Maintenance Requirements: To maximize performance and mitigate the memory effect, NiCd batteries generally require more attentive maintenance practices, including periodic deep discharge cycles. This maintenance overhead can be a disadvantage in applications where minimal user intervention is preferred.

Key Differences: Lithium-Ion vs. Nickel-Cadmium Batteries

Understanding the key differences between lithium-ion and nickel-cadmium batteries is essential for selecting the appropriate technology for your specific application. The table below provides a comprehensive comparison across critical performance parameters:

| Aspect | Lithium-Ion Battery | Nickel-Cadmium Battery |

|---|---|---|

| Energy Density | High (150-250 Wh/kg) | Moderate (45-80 Wh/kg) |

| Weight | Lightweight | Comparatively Heavier |

| Cycle Life | 300-500 cycles (consumer); 1000+ (industrial) | 1,000-2,000 cycles |

| Charging Speed | Fast | Moderate |

| Self-Discharge Rate | Low (1-2% per month) | High (10-20% per month) |

| Environmental Impact | Moderate (concerns with mining) | High (contains toxic cadmium) |

| Temperature Performance | Limited in extreme conditions | Excellent (-40°C to +70°C) |

| Memory Effect | None | Present |

| Initial Cost | Higher | Lower |

| Maintenance Requirements | Minimal | Moderate to High |

| Safety Considerations | Potential thermal runaway risks | Generally stable |

| Typical Applications | Mobile devices, EVs, renewable storage | Power tools, emergency systems, aviation |

The fundamental chemistry difference between these battery types drives their distinct performance characteristics. Lithium-ion batteries utilize lithium ions moving between electrodes, while NiCd batteries employ a reversible electrochemical reaction between nickel oxide hydroxide and metallic cadmium.

For most modern consumer applications, lithium-ion batteries provide superior energy density and convenience, making them the preferred choice for portable electronics and electric vehicles. However, NiCd batteries continue to excel in specialized scenarios requiring extreme temperature operation, high discharge rates, and long-term reliability in critical systems.

Which Battery Should You Choose?

Selecting the right battery technology depends entirely on your specific application requirements and priorities. Here’s a guided approach to help you make the most appropriate choice for your needs:

Consider Lithium-Ion Batteries For:

Mobile Consumer Electronics: Smartphones, laptops, tablets, and wearable devices benefit tremendously from lithium-ion’s high energy density, lightweight design, and fast charging capabilities. The absence of memory effect and minimal maintenance requirements align perfectly with consumer expectations for these devices.

Electric Vehicles and E-bikes: The superior energy density of lithium-ion batteries makes them ideal for transportation applications where range and weight are critical factors. For more information on optimizing lithium batteries for e-bikes, consult our comprehensive e-bike battery guide.

Renewable Energy Storage: Lithium-ion batteries, particularly LiFePO₄ variants, offer excellent cycle life and efficiency for solar and wind energy storage applications. Their low self-discharge rate ensures minimal energy loss during storage periods.

Space-Constrained Applications: Any application where volumetric energy density is a primary concern will generally benefit from lithium-ion technology. Our 18650 cell batteries offer an excellent balance of capacity and compact design.

Low-Maintenance Scenarios: Applications where regular maintenance is impractical or undesirable will benefit from lithium-ion’s minimal maintenance requirements and absence of memory effect.

Consider Nickel-Cadmium Batteries For:

Extreme Temperature Environments: Applications operating in very high or low temperatures, where lithium-ion performance would be compromised, are ideal candidates for NiCd technology.

High-Discharge Applications: Power tools, emergency backup systems, and other applications requiring high current delivery capabilities can benefit from NiCd’s excellent high-drain performance characteristics.

Critical Safety Systems: Aviation, emergency lighting, and medical equipment often rely on NiCd batteries for their exceptional reliability and well-established safety record in these critical applications.

Long-Term Deployment: Applications where batteries need to remain in service for many years with minimal replacement can benefit from NiCd’s exceptional cycle life, particularly in industrial settings.

Budget-Constrained Industrial Applications: When initial cost is a significant consideration and the application can accommodate the size and weight penalty, NiCd batteries may offer better long-term value.

Understanding discharge rate requirements is crucial for optimal battery selection. Our detailed battery C-rate guide provides valuable insights into how discharge rates affect battery performance and selection criteria.

Safety Considerations for Both Battery Types

Safety should always be a primary consideration when selecting, using, and disposing of any battery technology. Both lithium-ion and nickel-cadmium batteries present distinct safety considerations that should be thoroughly understood:

Lithium-Ion Battery Safety

Lithium-ion batteries can present serious safety hazards if not properly handled, stored, or charged. The potential for thermal runaway reactions—where internal battery temperature increases uncontrollably—can lead to fires or explosions in rare cases.

Key safety precautions include:

- Using only certified chargers designed specifically for lithium-ion batteries

- Avoiding physical damage to battery packs

- Preventing exposure to extreme temperatures

- Following manufacturer guidelines for charging parameters

- Implementing appropriate battery management systems for larger applications

- Adhering to proper shipping guidelines for lithium batteries to ensure compliance with transportation regulations

Modern lithium-ion batteries incorporate multiple safety mechanisms, including thermal fuses, current limiters, and pressure relief vents. At VADE Battery, we prioritize safety in all our designs, implementing comprehensive protection features to ensure reliable and secure operation.

Nickel-Cadmium Battery Safety

While NiCd batteries generally pose lower risks of thermal runaway compared to lithium-ion, they present significant environmental and health hazards due to their cadmium content.

Important safety considerations include:

- Proper disposal through certified recycling programs to prevent environmental contamination

- Avoiding exposure to damaged batteries that might leak toxic compounds

- Following appropriate charging protocols to prevent overheating

- Ensuring adequate ventilation in charging areas to disperse any gases produced during charging

- Compliance with regional regulations regarding the use and disposal of cadmium-containing products

The environmental impact of improper NiCd battery disposal cannot be overstated. Cadmium can contaminate soil and water supplies, potentially entering the food chain and causing significant health issues. Proper end-of-life management is essential for this battery technology.

Environmental Impact and Sustainability

As environmental concerns become increasingly prominent, understanding the sustainability implications of different battery technologies grows in importance:

Lithium-Ion Environmental Considerations

While lithium-ion batteries don’t contain highly toxic heavy metals like cadmium, they still present environmental challenges:

- Resource Extraction: Mining for lithium, cobalt, and nickel has significant environmental and social impacts, including water usage concerns in lithium-rich regions and ethical mining practices for cobalt

- Manufacturing Energy Intensity: Production of lithium-ion batteries requires substantial energy input, contributing to their carbon footprint

- Recycling Challenges: While technically recyclable, the complex composition of lithium-ion batteries makes efficient recycling more challenging than for some other battery types

- End-of-Life Management: Improper disposal can still lead to environmental contamination, though typically less severe than with cadmium-containing batteries

Despite these concerns, ongoing advances in lithium-ion recycling technology and the shift toward more sustainable cathode chemistries (like LFP) are improving the environmental profile of this battery technology.

Nickel-Cadmium Environmental Considerations

The environmental impact of NiCd batteries is primarily dominated by cadmium toxicity concerns:

- Toxic Material Content: Cadmium is highly toxic and can cause severe environmental damage and health problems if released through improper disposal

- Regulatory Restrictions: Many regions have implemented strict regulations or outright bans on certain applications of NiCd batteries due to environmental concerns

- Recycling Infrastructure: While well-established recycling processes exist for NiCd batteries, ensuring these batteries actually reach appropriate recycling facilities remains challenging

- Long-Term Environmental Persistence: Cadmium can persist in the environment for decades, potentially causing long-term ecological damage

Research indicates that waste nickel-cadmium batteries account for approximately 92% of the total cadmium in municipal waste, highlighting the importance of proper disposal and recycling programs.

Future Trends in Battery Technology

As we navigate through 2025, both lithium-ion and nickel-cadmium battery technologies continue to evolve, with several notable trends shaping their future development and applications:

Lithium-Ion Innovations

The lithium-ion landscape is experiencing rapid evolution across several fronts:

- Solid-State Electrolytes: The transition from liquid to solid electrolytes promises improved safety, energy density, and temperature performance

- Silicon-Based Anodes: Replacing traditional graphite with silicon-based materials to significantly increase energy density

- Cobalt-Free Cathodes: Development of cathode materials that eliminate or drastically reduce cobalt content, addressing both cost and ethical sourcing concerns

- Improved Recycling Methods: Advanced processes for more efficient recovery of valuable materials from spent batteries

- Enhanced Safety Mechanisms: Continued evolution of protection systems to further reduce thermal runaway risks

These innovations are gradually addressing the primary limitations of current lithium-ion technology, potentially extending their dominance in the battery market.

Nickel-Cadmium Developments

While regulatory pressure continues to limit NiCd applications, several developments are helping maintain their relevance in specialized niches:

- Reduced Cadmium Content: Research into formulations that maintain performance while minimizing cadmium usage

- Improved Recycling Infrastructure: Enhancement of collection and recycling systems to minimize environmental impact

- Performance Optimization: Continued refinement of existing chemistry to maximize cycle life and temperature performance for critical applications

- Specialized Application Focus: Concentration on niche markets where NiCd’s unique attributes remain advantageous despite regulatory pressure

As environmental regulations tighten globally, the long-term future of NiCd technology will likely involve increasing specialization into applications where their unique performance characteristics justify their continued use despite environmental concerns.

Why Choose VADE Battery for Your Energy Storage Needs in 2025

At VADE Battery, we deliver custom rechargeable solutions that precisely match your performance requirements while maximizing safety and value. Our specialty lies in creating tailored 18650, Li-ion, Lithium polymer, and LiFePO4 battery packs that solve complex energy challenges for clients worldwide.

Our Differentiating Principles:

- Safety Through Engineering Excellence: Every battery design incorporates multiple protection mechanisms and premium components, backed by our comprehensive battery storage safety and shipping compliance protocols.

- Application-Optimized Performance: We analyze your specific use case parameters to deliver battery solutions with ideal discharge characteristics, temperature tolerance, and longevity for your exact application needs.

- Value-Driven Solutions: Our global supply chain relationships and efficient manufacturing processes enable competitive pricing without compromising performance or reliability.

- Cross-Chemistry Expertise: Whether your application demands the high energy density of lithium-ion or the extreme temperature resilience of alternative chemistries, our technical team provides data-driven guidance to identify your optimal technology match.

Explore our 3.7V 18650 cells and other specialized battery options to find the foundation for your next custom energy solution. Contact us today to discuss your specific battery requirements.

Frequently Asked Questions

Are nickel batteries better than lithium?

The superiority of nickel-based batteries versus lithium-based batteries depends entirely on your specific application requirements. Nickel batteries (particularly NiCd) excel in extreme temperature environments, high-discharge applications, and scenarios requiring exceptional cycle life. Lithium batteries offer superior energy density, lighter weight, and greater convenience for most consumer applications. The “better” technology is the one that more closely matches your particular performance priorities, environmental conditions, and budget constraints.

Can I replace a NiCad battery with a lithium-ion battery?

Replacing a NiCad battery with a lithium-ion battery requires careful consideration of several factors:

- Voltage Characteristics: NiCd cells provide 1.2V per cell versus 3.6-3.7V for lithium-ion cells, requiring different cell configurations

- Charging Requirements: Lithium-ion batteries require specialized charging circuits with precise voltage control

- Protection Circuits: Lithium-ion implementations typically require additional protection against overcharge, over-discharge, and short-circuit conditions

- Physical Dimensions: Form factor differences may necessitate mechanical adaptations

- Temperature Operating Range: Application environment must fall within lithium-ion’s more limited temperature tolerance

While feasible in many cases, such replacements should be approached systematically with proper engineering consideration of these factors. At VADE Battery, we can evaluate your specific requirements and determine if such a replacement would be beneficial for your application.

Is lithium-ion battery better than nickel cadmium for power tools?

For most modern power tools, lithium-ion batteries offer several advantages over nickel-cadmium:

- Higher Energy Density: Lithium-ion provides longer runtime in a more compact, lightweight package

- No Memory Effect: Eliminates the need for complete discharge before recharging

- Lower Self-Discharge: Tools remain charged longer when not in use

- Faster Charging: Reduces downtime between uses

However, nickel-cadmium batteries maintain advantages in certain power tool applications:

- Extreme Temperature Performance: Superior operation in very cold environments

- High-Discharge Capability: Excellent performance in high-current demand situations

- Durability: Greater tolerance for rough handling and adverse conditions

- Lower Cost: More economical for budget-conscious applications

Professional users should evaluate their specific usage patterns, environmental conditions, and performance priorities when selecting between these technologies for power tool applications.

How long will NiCad batteries last?

Nickel-cadmium batteries are renowned for their exceptional cycle life. Under optimal conditions and with proper maintenance:

- Cycle Life: NiCd batteries typically deliver 1,000-2,000 complete charge-discharge cycles before significant capacity degradation

- Calendar Life: In industrial applications with proper maintenance, NiCd batteries can remain in service for 15-20+ years

- Maintenance Impact: Regular deep discharge cycles and proper charging practices significantly extend usable life

- Temperature Effects: Operating within recommended temperature ranges maximizes longevity

Factors that negatively impact NiCd battery lifespan include continuous overcharging, operation at elevated temperatures, and extended periods of deep discharge. With appropriate care and usage patterns, NiCd batteries provide exceptional longevity compared to most other rechargeable battery technologies.

Are NiCad batteries illegal?

Nickel-cadmium batteries are not universally illegal, but their use has been increasingly restricted in many regions due to environmental concerns related to cadmium toxicity:

- European Union: The EU Battery Directive (2006/66/EC) restricted the use of cadmium in batteries to less than 0.002% by weight, with exemptions for emergency systems, medical equipment, and certain power tools (though these exemptions have narrowed over time)

- United States: No comprehensive federal ban exists, but some states have implemented restrictions on certain applications

- Global Trend: The regulatory trajectory continues toward tighter restrictions on cadmium-containing products

These regulations typically focus on consumer applications rather than specialized industrial or critical safety systems where NiCd’s unique performance characteristics remain valuable. Always check current regulations in your specific region regarding the sale, use, and disposal of NiCd batteries.

Why was cadmium banned in batteries?

Cadmium restrictions in batteries stem primarily from significant environmental and health concerns:

- Environmental Toxicity: Cadmium is highly toxic to ecosystems, contaminating soil and water when improperly disposed of in landfills

- Bioaccumulation: Cadmium can accumulate in the food chain, with concentrations increasing at higher trophic levels

- Human Health Impact: Exposure to cadmium has been linked to kidney damage, bone disease, and increased cancer risk

- Long Environmental Persistence: Once released, cadmium can persist in the environment for decades

According to research, waste nickel-cadmium batteries contribute approximately 92% of the total cadmium in municipal waste, highlighting the significance of this specific application to overall cadmium pollution concerns. These serious risks prompted regulatory bodies worldwide to implement restrictions despite NiCd’s valuable performance characteristics.