Lithium-ion battery packs power everything from smartphones to electric vehicles, but their complex engineering is often overlooked. At Vade Battery, we specialize in designing custom rechargeable battery solutions—including 18650 cells, Li-ion packs, Lithium polymer batteries, and LiFePO4 systems—that prioritize safety, power efficiency, and cost-effectiveness. Whether you’re developing medical devices or grid storage systems, understanding the components of a lithium-ion battery pack is critical to optimizing performance. In this guide, we’ll break down each element, explain how they work together, and showcase how Vade Battery’s engineering expertise delivers reliable solutions for global clients.

What Makes Up a Lithium-Ion Battery Pack?

A lithium-ion battery pack is more than just a cluster of cells—it’s a meticulously engineered system designed to store energy safely and deliver power efficiently. Key components include:

- Lithium-ion cells: The electrochemical units that store energy.

- Battery Management System (BMS): The “brain” monitoring safety and performance.

- Passive components: Busbars, fuses, and adhesives that ensure structural and electrical integrity.

- Enclosure: A protective housing with thermal management features.

At Vade Battery, we tailor these components to meet specific voltage, capacity, and environmental requirements. For example, our ultra-low-temperature Li-ion batteries integrate advanced heating elements for sub-zero environments, while our high-capacity 18650 packs optimize energy density for portable electronics.

Lithium-Ion Cells

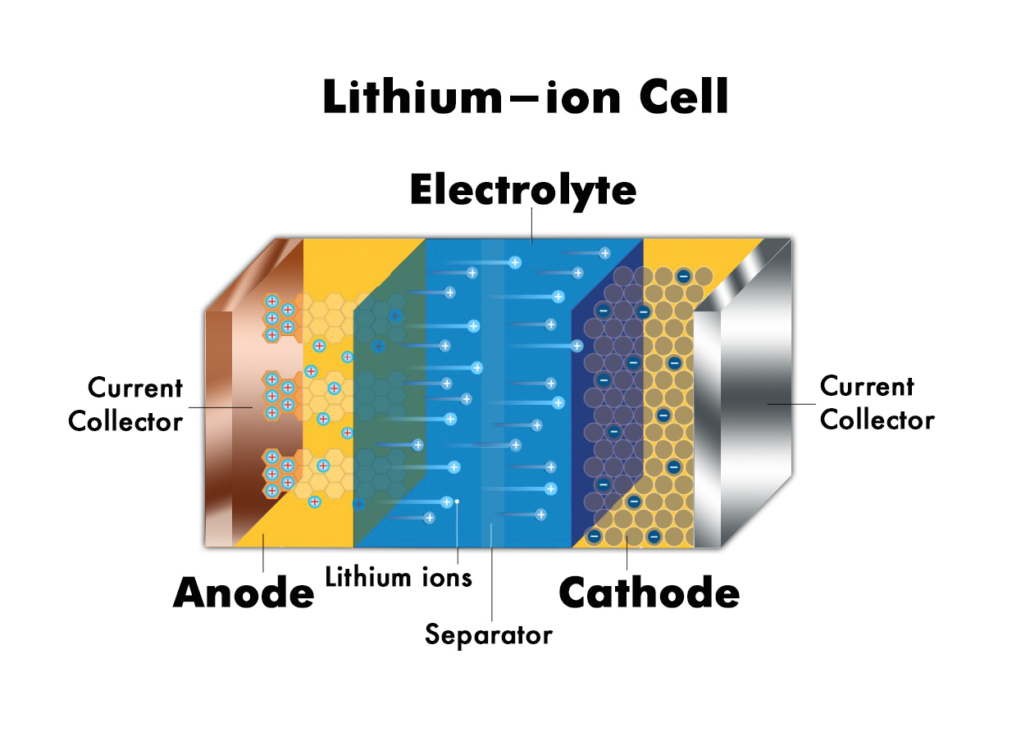

What Are Lithium-Ion Cells?

Lithium-ion cells convert chemical energy into electrical energy through the movement of lithium ions between a graphite anode and a metal oxide cathode. Their performance hinges on three factors: chemistry, form factor, and manufacturing quality.

Common Cell Chemologies:

| Chemistry | Voltage | Energy Density | Safety | Best For |

|---|---|---|---|---|

| LiFePO4 | 3.2V | Moderate | High | Solar storage, EVs |

| NMC | 3.6V | High | Medium | Power tools, EVs |

| LCO | 3.6V | Very High | Low | Consumer electronics |

Vade Battery’s LiFePO4 cells are ideal for applications requiring long cycle life and thermal stability, such as off-grid energy storage. In contrast, our NMC-based packs deliver unmatched energy density for electric vehicles.

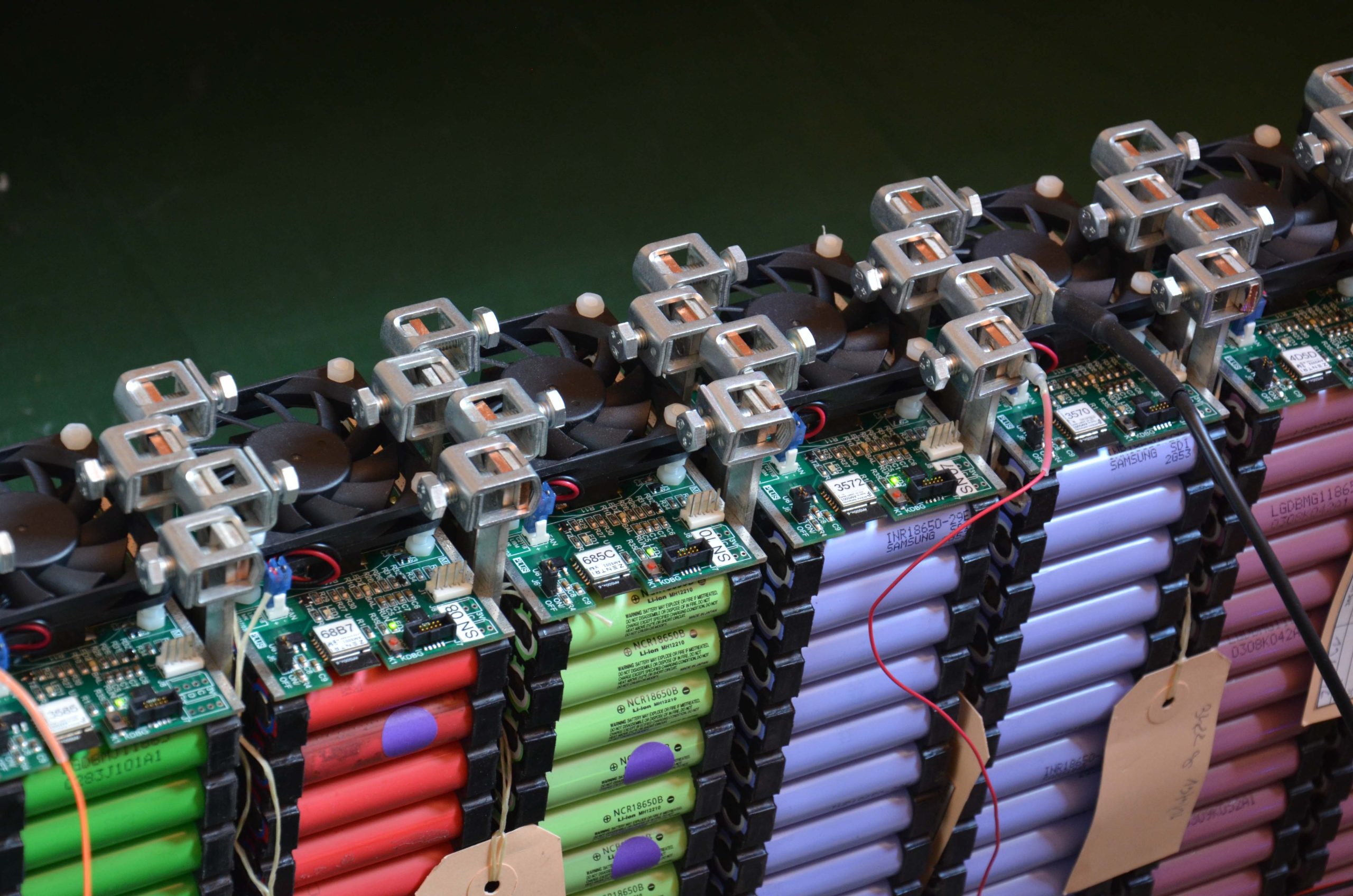

Cell Form Factors:

- 18650 Cylindrical Cells: Widely used in laptops and power banks. Vade’s 18650 battery packs offer 2,000+ cycles at 80% capacity retention.

- Pouch Cells: Lightweight and flexible, perfect for wearables.

- Prismatic Cells: High volumetric efficiency for EVs and industrial equipment.

Case Study: A robotics company needed a compact 24V battery pack with a 10-year lifespan. We used LiFePO4 prismatic cells with a modular design, achieving 15% higher energy density than industry benchmarks. Contact us for similar custom solutions.

Battery Management System (BMS)

What Does a BMS Do?

The BMS is the unsung hero of lithium-ion packs. It ensures safety by:

- Monitoring individual cell voltages (±15mV accuracy).

- Balancing cells during charging (passive or active balancing).

- Enabling overcurrent, overtemperature, and short-circuit protection.

Vade Battery’s proprietary BMS includes active balancing technology, which redistributes energy between cells to extend pack lifespan by up to 30%. For high-voltage systems like our 51.2V LiFePO4 packs, the BMS integrates galvanic isolation to prevent ground faults.

Key BMS Features in Vade Battery Packs:

- Multi-layer safety protocols: Redundant sensors and fail-safe contactors.

- SOC/SOH estimation: ±3% accuracy for real-time capacity tracking.

- CAN bus communication: Seamless integration with industrial IoT systems.

Quote from a Client:

“Vade’s BMS eliminated cell voltage drift in our solar storage units, reducing maintenance costs by 40%.” – Energy Solutions Engineer, Germany

Passive Components

What Are Passive Components?

These non-active parts ensure electrical stability, thermal regulation, and mechanical durability:

- Busbars:

- Material: Oxygen-free copper for minimal resistance (<0.5mΩ).

- Design: Laser-welded interconnects to handle currents up to 500A.

- Thermal Interface Materials (TIMs):

- Silicone-based pads with 5W/mK conductivity for efficient heat dissipation.

- Fuses and Contactors:

- Resettable PPTC fuses for overcurrent protection.

In our 48V lithium polymer packs, we use epoxy-coated busbars to prevent corrosion in humid environments—a common pain point in marine applications.

Battery Pack Enclosure

What Is the Role of a Battery Enclosure?

The enclosure is the armored shell safeguarding sensitive lithium-ion components from physical damage, moisture, and electromagnetic interference. At Vade Battery, enclosures are engineered to meet IP67 or higher ratings for harsh environments, using materials like:

- Anodized aluminum: Lightweight, corrosion-resistant, and excellent for heat dissipation.

- ABS-PC blends: High-impact plastics for lightweight consumer electronics.

- Carbon fiber composites: Extreme durability for aerospace and military applications.

Key Design Considerations:

- Modularity: Our custom lithium-ion battery packs feature snap-in modules for easy scalability.

- Thermal regulation: Integrated cooling channels for liquid or air-based systems.

- EMI shielding: Metal-coated interiors block interference in medical devices.

Case Study: A drone manufacturer required a waterproof 36V battery pack capable of surviving -20°C temperatures. We developed an IP68-rated aluminum enclosure with silicone gaskets and built-in heating pads, enabling reliable operation in Arctic surveys.

Thermal Management Systems

Why Is Thermal Management Critical?

Lithium-ion cells degrade rapidly outside their 15–35°C operational window. Vade Battery’s thermal systems maintain optimal temperatures using:

| Method | Pros | Best For |

|---|---|---|

| Liquid Cooling | High heat transfer efficiency | EVs, grid storage |

| Phase Change Materials | Passive, no power needed | Consumer electronics |

| Forced Air | Low cost, simple design | Power tools, UPS systems |

For extreme conditions, our ultra-low-temperature Li-ion batteries use self-heating graphite layers to pre-warm cells to -30°C, ensuring instant startup in cold climates.

Innovation Spotlight:

Vade’s dual-mode cooling combines liquid and thermoelectric systems for industrial robots, reducing peak temperatures by 25°C during rapid charging.

Additional Components

What Extra Features Can a Battery Pack Include?

- Precharge Circuits:

- Limit inrush currents when connecting to inverters, protecting contactors.

- Used in our 72V EV packs to prevent arcing.

- Wireless Monitoring:

- Bluetooth or LoRaWAN modules for remote SOC/SOH tracking.

- Cell Switching Technology:

- Isolates faulty cells without shutting down the entire pack.

Example: A marine energy storage project required failsafe operation in saltwater environments. We added corrosion-resistant SS316 terminals and a moisture-detection circuit that triggers automatic shutdown.

Lithium-Ion Battery Pack Applications

1. Electric Vehicles (EVs):

- Requirements: High energy density (≥250 Wh/kg), fast charging, 10+ year lifespan.

- Vade Solution: NMC-based 51.8V battery packs with liquid cooling and ISO 26262-certified BMS.

2. Medical Devices:

- Requirements: Compact size, biocompatible materials, zero leakage risk.

- Vade Solution: Flexible lithium polymer cells with UL 60601-1 certification for MRI machines.

3. Renewable Energy Storage:

- Requirements: Low cost per cycle, LiFePO4 chemistry, modular design.

- Vade Solution: Scalable 48V LiFePO4 racks with 6,000-cycle lifespan.

Client Success Story:

A solar farm in Australia reduced its LCOE (Levelized Cost of Energy) by 18% using Vade’s cycle-optimized LiFePO4 packs with active balancing.

Lithium-Ion Battery Safety

How Does Vade Battery Mitigate Safety Hazards?

- Cell-Level Protections:

- CID (Current Interrupt Device): Permanently disconnects cells during overpressure.

- PTC (Positive Temperature Coefficient) Resistors: Limit current during overheating.

- Pack-Level Safeguards:

- Flame-retardant separators: Self-extinguishing membranes (UL 94 V-0 rated).

- Ventilation channels: Redirect thermal runaway gases away from users.

- Certifications:

- UN 38.3 (transport), IEC 62133 (safety), and CE/UKCA compliance.

Quote from a Client:

“After switching to Vade’s LiFePO4 packs, we’ve had zero thermal incidents in 3 years.” – Industrial Equipment OEM, Canada

Conclusion

Lithium-ion battery packs are evolving rapidly, driven by demands for higher energy density, faster charging, and absolute safety. At Vade Battery, we stay ahead of these trends through:

- Advanced BMS algorithms for predictive maintenance.

- Hybrid cooling systems that adapt to dynamic loads.

- Custom cell configurations for niche applications.

Whether you need a 12V backup battery for telecom systems or a high-voltage 72V pack for electric boats, our engineering team tailors solutions that balance performance, safety, and cost.

Ready to Power Your Innovation?

Submit your custom battery requirements or contact our experts at service@vadebattery.com for a free consultation.