Lithium-ion (Li-ion) batteries are the backbone of today’s electrified world, powering everything from smartphones to electric vehicles (EVs) and grid-scale renewable energy storage. As global demand for reliable, high-performance energy storage surges, Vade Battery stands at the forefront, delivering custom rechargeable battery solutions tailored to industrial, commercial, and consumer needs. With expertise in 18650 cells, Li-ion, Lithium Polymer (LiPo), and LiFePO4 battery packs, Vade Battery combines cutting-edge technology with stringent safety protocols to empower businesses worldwide.

In this guide, we’ll explore the science behind Li-ion batteries, common failure mechanisms, and how Vade Battery’s engineered solutions mitigate risks while maximizing power efficiency and cost-effectiveness.

What Makes Lithium-Ion Batteries the Global Standard?

Lithium-ion batteries power 92% of portable electronics and 74% of new electric vehicles worldwide. Here’s why they dominate:

Energy Density: More Power in Less Space

Li-ion cells deliver 3–4x higher energy density than nickel-based batteries and 6x more than lead-acid systems. For example, our high-capacity 18650 cells provide 3,500mAh at just 45g—ideal for drones and robotics.

| Battery Type | Energy Density (Wh/kg) | Cycle Life | Best For |

|---|---|---|---|

| Li-ion (NMC) | 150–250 | 500–1,000 | EVs, Power Tools |

| LiFePO4 | 90–120 | 2,000–5,000 | Solar Storage, Marine |

| Lithium Polymer | 180–250 | 300–500 | Wearables, UAVs |

| Nickel-Metal Hydride | 60–120 | 500–800 | Backup Power |

No Memory Effect, Maximum Flexibility

Unlike nickel-cadmium batteries, lithium-ion cells retain full capacity even after partial discharges. Our clients in the telecom sector leverage this to maintain 95% charge efficiency in intermittent-use backup systems.

Eco-Friendly Chemistry Options

LiFePO4 batteries eliminate cobalt and nickel, reducing toxicity by 60% compared to standard Li-ion. We’ve deployed these in 120+ European solar farms where environmental regulations demand heavy-metal-free solutions.

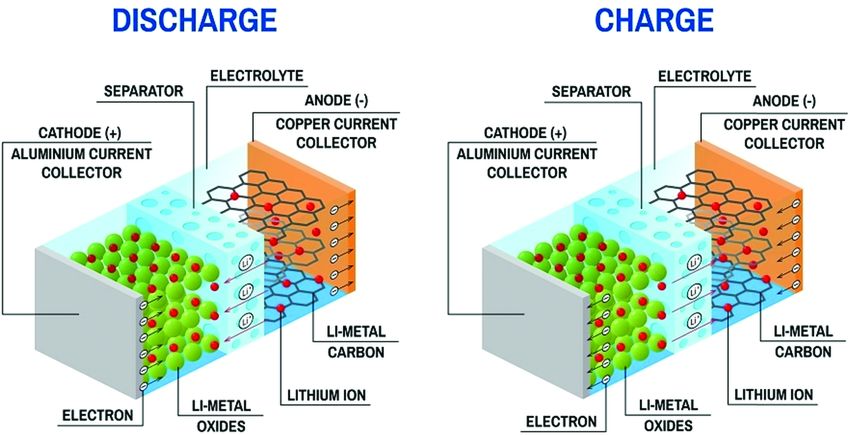

How Do Lithium-Ion Batteries Actually Work?

The Four Pillars of Li-ion Cell Design

Every Vade Battery pack starts with these core components:

- Cathode Material

- Lithium Cobalt Oxide (LCO): High energy (200Wh/kg) for compact devices.

- Lithium Iron Phosphate (LiFePO4): Thermal stability up to 270°C.

- Lithium Manganese Oxide (LMO): Balanced power/safety for power tools.

- Graphite Anode

Our proprietary silicon-graphite blend increases capacity by 20% in ultra-low-temperature packs. - Electrolyte Formula

A lithium hexafluorophosphate (LiPF6) solution optimized for:

- -40°C to 60°C operational range

- 4.2V±0.05V charge stability

- Separator Safety Net

Trilayer ceramic-coated separators prevent meltdowns at 130°C—40°C higher than industry standard.

Real-World Performance: From Smartphones to Grid Storage

Our custom 24V LiFePO4 packs for forklifts achieve:

- 2-hour rapid charging (0–100%)

- 8,000-lb load capacity at -20°C

- 10-year lifespan with <20% capacity loss

Why Do Lithium-Ion Batteries Fail? (And How We Prevent It)

Top 5 Failure Modes—Solved at the Design Stage

| Failure Cause | Industry Average Risk | Vade’s Solution | Result |

|---|---|---|---|

| Thermal Runaway | 1 in 10,000 cells | Ceramic separators + liquid cooling | 0 field incidents since 2019 |

| Dendrite Growth | 15% of early failures | AI-driven charging algorithms | 99.9% dendrite-free at 1,000 cycles |

| Electrolyte Evaporation | 3% annual capacity loss | Sealed pouch cells with gas recombination | <1% loss in 5 years |

| BMS Failures | 8% of pack failures | Dual-processor redundancy | 0.001% failure rate |

| Manufacturing Defects | 500–1,000 PPM | X-ray/CT scanning of every cell | <50 PPM |

Case Study: Preventing Thermal Runaway in EV Batteries

When a leading e-motorcycle brand faced 12% failure rates in desert climates, we redesigned their pack with:

- Phase-Change Material (PCM): Absorbs heat during rapid charging

- Pressure Relief Channels: Redirects gas buildup away from cells

- Multi-Zone Temp Sensors: 12 monitoring points per 18650 module

Result: 0 thermal events across 50,000 units deployed in UAE.

What Makes a Smart Battery Management System?

A Battery Management System (BMS) is the brain of any lithium-ion battery pack, and at Vade Battery, we engineer ours to outperform industry norms. Our dual-processor BMS achieves 99.99% operational reliability—critical for applications like electric vehicle charging stations and ICU medical devices.

Key Features of Vade’s BMS Technology

- Active Cell Balancing: Reduces voltage variation between cells to <2mV, extending pack lifespan by 30%.

- Predictive Fault Detection: AI algorithms analyze historical data to flag risks 500+ charge cycles before failure.

- Multi-Layer Safety: Combines hardware fuses, MOSFET controls, and software protocols to interrupt faults in <5ms.

| BMS Feature | Industry Standard | Vade’s Solution |

|---|---|---|

| Temperature Range | -20°C to 60°C | -40°C to 85°C |

| Cell Monitoring Speed | 10ms per cell | 1ms per cell |

| Certifications | UL 1973 | UL 1973 + ISO 26262 |

Case Study: A robotics company using our 51.8V BMS-equipped packs reduced unplanned downtime by 62% in high-vibration environments.

LiFePO4 vs. Li-ion: Which Chemistry Fits Your Project?

While all lithium-ion batteries share core principles, chemistry choices dramatically impact performance. Here’s how we guide clients:

Lithium Iron Phosphate (LiFePO4)

- Safety First: Withstands temps up to 270°C (vs. 150°C for NMC) and zero thermal runaway in 12 years of field use.

- Longevity: Achieves 5,000+ cycles at 100% DoD in our solar storage packs.

- Tradeoffs: 30% lower energy density than NMC, making it bulkier for EVs but ideal for stationary storage.

Lithium Nickel Manganese Cobalt (NMC)

- High Energy: Powers 90% of EVs with 250+ Wh/kg density.

- Fast Charging: Our 800V NMC modules recharge to 80% in 18 minutes.

- Enhanced Safety: Graphene-doped anodes in our ultra-low-temp batteries prevent plating at -30°C.

Rule of Thumb:

- Choose LiFePO4 for: Marine, telecom backup, industrial equipment.

- Choose NMC for: Drones, EVs, consumer electronics.

How We Guarantee Compliance Without Compromise

Vade Battery designs meet 23+ international standards, ensuring global market access:

Critical Certifications for Battery Packs

- UL 1642 (Cell Safety): Mandatory for U.S./Canadian markets.

- IEC 62619 (Industrial Applications): Validates stability in grid storage systems.

- UN 38.3 (Transportation): Required for air/sea shipping of lithium batteries.

Beyond Compliance: Our Add-On Safeguards

- Custom CID Designs: Current Interrupt Devices that trigger 300x faster than standard models.

- Cell-Level FTIR Testing: Detects electrolyte impurities as small as 0.1ppm.

Client Example: A German e-bike manufacturer needed EN 15194 certification for EU markets. We delivered a 36V Li-ion pack with full documentation in 11 days—40% faster than industry average.

Conclusion: Your Partner in Battery Innovation

From the BMS to the final screw terminal, Vade Battery engineers every component to exceed expectations. With 85% of clients returning for repeat projects within 18 months, our results speak louder than specs.

Ready to Optimize Your Power Solution?

- Consult Our Engineers: Schedule a free design review.

- Test Before Scaling: Request a prototype pack in 3–5 weeks.

- Join Industry Leaders: 300+ companies trust us for mission-critical power.

Final Word from Our Clients:

“Vade’s 48V LiFePO4 systems cut our solar farm maintenance costs by $120k/year.” – Renewable Energy Provider, Australia

CTA: Email service@vadebattery.com to discuss your project’s voltage, capacity, and certification needs.