Car battery weight varies significantly—from 10 pounds for lightweight lithium options to over 70 pounds for heavy-duty lead-acid models—and directly impacts your vehicle’s performance, fuel efficiency, and handling. Whether you’re replacing your battery, upgrading for better performance, or selecting components for a custom build, understanding battery weight fundamentals is essential for making informed decisions. This data-driven guide analyzes weight specifications across all major battery types, provides weight-to-performance ratios, and offers expert advice on selecting the optimal battery weight for your specific vehicle and driving needs.

Understanding Car Battery Weight Basics

Car battery weight varies significantly depending on the vehicle type, battery chemistry, and intended application. Let’s break down the fundamentals of battery weight and why it matters.

Average Weight Ranges for Different Vehicle Types

Car battery weights span a wide spectrum depending on the vehicle they’re designed for. Here’s a detailed breakdown:

| Vehicle Type | Battery Weight Range |

|---|---|

| Standard Cars | 30-50 pounds (13.6-22.7 kg) |

| Lightweight Performance | 10-25 pounds (4.5-11.3 kg) |

| Hybrid Vehicles | 100-300 pounds (45.4-136.1 kg) |

| Electric Vehicles | 1,000-2,000 pounds (453.6-907.2 kg) |

| Heavy-duty Vehicles | 50-70 pounds (22.7-31.8 kg) |

As we move through 2025, manufacturers continue to innovate in battery technology, gradually reducing weights while maintaining or improving performance.

Why Battery Weight Matters for Your Car

Battery weight significantly impacts several aspects of your vehicle’s performance and operation:

- Fuel Efficiency: Each additional pound requires more energy to move, potentially decreasing fuel economy

- Acceleration Performance: Heavier batteries demand more energy during acceleration

- Vehicle Range: For electric vehicles, battery weight directly influences range capacity

- Maintenance Requirements: Extra weight increases strain on suspension components and brakes

- Installation Safety: Proper handling during installation requires awareness of weight

According to recent automotive engineering studies, reducing battery weight by just 10% can improve fuel efficiency by up to 2-3% in conventional vehicles. For more information on how battery weight affects vehicle efficiency, check out this article on battery efficiency from Vade Battery.

Weight Distribution and Vehicle Balance

Strategic battery placement is vital to your car’s overall balance. Manufacturers position batteries to optimize weight distribution, typically placing them low in the chassis to enhance stability.

In electric vehicles, batteries can constitute up to 25 percent of the car’s total weight. This distribution actually improves stability and safety in various driving conditions by lowering the center of gravity. Many sports car manufacturers have adopted similar principles, placing heavy components like batteries lower in the chassis to improve handling dynamics.

Common Car Battery Types and Their Weights

Our analysis of car battery types reveals distinct categories with different weights and applications. Understanding these differences helps you select the right battery for your specific needs.

Traditional Lead-Acid Batteries (25-50 lbs)

Traditional lead-acid batteries remain the most common choice in the automotive industry, particularly for conventional vehicles with internal combustion engines. These batteries typically weigh between 30 to 50 pounds (13.6 to 22.7 kg).

The substantial weight comes from lead plates and sulfuric acid solution that store and release electrical energy. Different groups of lead-acid batteries have varying weights:

- Group 24 batteries: 43-57 pounds (19.5-25.8 kg)

- Group 35 batteries: 31-50 pounds (14-22.7 kg)

- Group 51/51R batteries: 25-43 pounds (11.4-19.5 kg)

While these batteries are heavier, they remain popular due to their reliability, affordability, and widespread availability. For conventional vehicles, their proven technology continues to offer excellent value. Learn more about lead-acid battery technology from Wikipedia.

AGM and Gel Batteries (30-60 lbs)

Absorbent Glass Mat (AGM) and Gel batteries represent advanced versions of lead-acid technology with special design features:

| Battery Type | Weight Range | Key Features |

|---|---|---|

| AGM Batteries | 30-45 lbs (13.6-20.4 kg) | Spill-proof design, better vibration resistance, longer life |

| Gel Batteries | 30-40 lbs (13.6-18.1 kg) | Gel electrolyte, excellent deep cycle capabilities, maintenance-free |

These batteries deliver superior performance and durability compared to traditional lead-acid batteries. AGM batteries can be mounted in various positions thanks to their sealed construction, making them ideal for modern vehicles with complex electrical systems and start-stop technology. For specialized applications that require reliable AGM batteries, Vade Battery offers several high-performance options.

Lithium-Ion Batteries (10-25 lbs)

Lithium-ion batteries represent the cutting edge of automotive battery technology, with weights between 10 to 20 pounds (4.5-9.1 kg). This dramatic weight reduction makes them increasingly popular for high-performance vehicles where every pound matters.

Specific group weights include:

- Group 34 lithium: ~14 pounds (6.3 kg)

- Group 35 lithium: ~16 pounds (7.3 kg)

- Group 94R lithium: ~17 pounds (7.7 kg)

The weight difference between lithium-ion and traditional lead-acid batteries can reduce overall vehicle weight by 20-40 pounds, providing a significant advantage for performance applications. As of 2025, advances in lithium battery technology have made them increasingly affordable, though they still command a premium over traditional options. For more information on lithium battery technology, visit Battery University’s comprehensive guide.

Heavy-Duty Car Batteries (50-70 lbs)

Heavy-duty vehicles like trucks, large SUVs, and commercial vehicles require more powerful batteries to handle increased electrical demands and larger engines. These specialized batteries typically weigh between 50 to 70 pounds (22.7 to 31.8 kg).

The extra weight comes from additional lead plates, reinforced construction, and higher capacity designs. Some specialized batteries for industrial or commercial vehicles can weigh even more depending on their specific requirements. These batteries are engineered to withstand harsher conditions, provide more cold cranking amps, and offer longer reserve capacity.

Factors Influencing Car Battery Weight

Multiple elements determine how much a car battery weighs. Understanding these factors helps explain weight variations between different models and types.

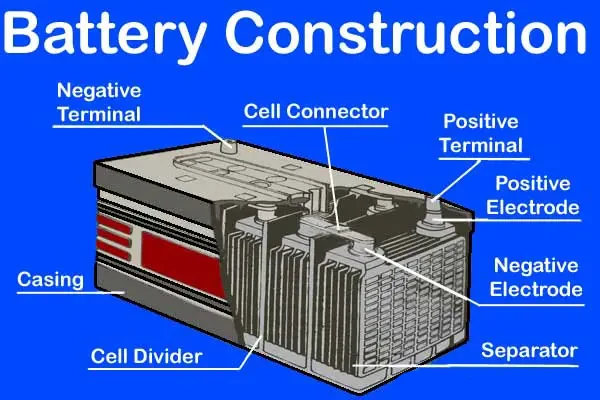

Battery Structure and Components

Understanding a battery’s internal components helps explain its weight distribution:

- Lead Plates: These are the heaviest components in traditional batteries, accounting for approximately 60% of total weight

- Electrolyte Solution: The sulfuric acid and water mixture adds substantial weight, comprising roughly 25-30% of the total

- Plastic or Metal Casing: The outer shell that protects internal components contributes 10-15% to overall weight

- Connectors and Terminals: Made of copper, lead, or other metals, these account for around 5% of total battery weight

In lithium batteries, the weight distribution shifts dramatically, with lighter lithium cells replacing heavy lead plates. For detailed information about battery components and construction, Vade Battery offers an educational resource section.

Battery Capacity

Battery capacity, measured in amp-hours (Ah), directly correlates with weight. Higher capacity batteries contain more active materials to store additional charge, increasing their overall weight.

As a rule of thumb, a 100 Ah battery will be substantially heavier than a 50 Ah battery because it requires more lead plates and electrolyte to store the additional charge. If your vehicle has high energy demands, you might need a higher capacity battery, which will be heavier.

The 2025 automotive market has seen increasing demand for higher capacity batteries to support advanced vehicle electronics and comfort features, pushing manufacturers to develop more energy-dense solutions that maintain capacity while minimizing weight.

Materials Used

The density and quality of materials significantly impact battery weight:

- Plate Material Density: Higher density lead alloys store more energy but add weight

- Electrolyte Concentration: Stronger acid solutions provide better conductivity but weigh more

- Casing Construction: Reinforced casings offer better protection but increase overall weight

- Terminal Design: Larger, more robust terminals add minimal weight but improve connectivity

Premium batteries often use higher quality materials that might weigh more but deliver better performance and longevity. For instance, batteries with thicker lead plates can store more energy and last longer but will add to the battery’s weight.

Size and Design

Physical dimensions directly influence battery weight. Larger batteries naturally contain more materials and therefore weigh more. The battery’s size class, often designated by group number in North America, provides a standardized way to understand approximate weight ranges.

Modern battery designs increasingly focus on optimizing weight-to-power ratios. Innovations in cell architecture, material science, and manufacturing techniques have enabled significant weight reductions without compromising performance. Some 2025 models feature space-saving designs that reduce weight by up to 15% compared to their 2020 counterparts.

Impact on Vehicle Performance

Battery weight affects your vehicle in several important ways that extend beyond simply providing electrical power.

Effect on Fuel Efficiency

Every pound matters when it comes to fuel efficiency. Heavier batteries require more energy to move, forcing the engine to work harder and consume more fuel. This relationship becomes particularly important in smaller vehicles where battery weight represents a higher percentage of total vehicle weight.

According to recent automotive engineering studies, a 10-pound reduction in battery weight can improve fuel efficiency by approximately 0.1-0.2 mpg in conventional vehicles. While this might seem minimal, it adds up over the vehicle’s lifetime.

For electric vehicles, battery weight has an even more direct impact on range and efficiency. EV manufacturers in 2025 are investing heavily in lightweight battery technologies to extend range capabilities without increasing battery size.

Handling and Performance Considerations

Weight distribution significantly influences vehicle handling characteristics. Batteries are typically placed to optimize balance and stability:

- In front-engine vehicles, batteries are often positioned near the front to maintain weight distribution

- In performance vehicles, batteries may be centrally located or moved rearward to improve handling dynamics

- In electric vehicles, battery packs are generally mounted low in the chassis to lower the center of gravity

The weight and placement of your vehicle’s battery can affect steering response, braking distance, and overall handling feel. Performance enthusiasts often consider lightweight lithium batteries as a way to improve vehicle dynamics, especially in racing or track-day applications. Vade Battery’s performance series offers options specifically designed to optimize vehicle handling.

Longevity of Vehicle Components

The additional weight from a heavy battery can increase strain on various vehicle components:

- Suspension systems face increased load, potentially leading to faster wear of springs, shocks, and bushings

- Braking systems must work harder to stop the additional weight

- Engine mounts bear extra stress during acceleration and deceleration

- Chassis components experience more strain, particularly over rough surfaces

Over time, this extra weight can contribute to accelerated wear and more frequent maintenance requirements. For vehicles driven primarily on rough roads or in harsh conditions, this consideration becomes even more important when selecting a battery.

How to Determine Your Car Battery’s Weight

Finding the exact weight of your car battery can be accomplished through several reliable methods.

BCI Group Number Reference

The Battery Council International (BCI) Group Number provides a standardized reference for battery specifications, including approximate weight ranges. This number indicates the battery’s physical size, terminal configuration, and type.

While the BCI Group Number doesn’t directly specify weight, batteries within the same group typically fall within a consistent weight range. You can reference comprehensive BCI group charts to estimate your battery’s weight based on its group number.

For a detailed breakdown of BCI group specifications, including weight ranges, this automotive reference guide provides reliable information.

Checking Manufacturer Specifications

The most accurate source for battery weight information is the manufacturer’s documentation. You can find this information through several channels:

- Battery label: Many batteries list their weight directly on the case

- Manufacturer’s website: Look up your specific battery model on the producer’s site

- Product catalogs: Detailed specifications are often available in print or PDF catalogs

- Technical support: Contact the manufacturer’s customer service for exact specifications

Most reputable battery manufacturers maintain comprehensive online databases of their products’ specifications. If you’re considering a battery from Vade Battery, you can find detailed weight specifications on their product specification page.

Using Owner’s Manual

Your vehicle’s owner’s manual often provides specifications for the recommended battery, including its weight. This information is typically found in the maintenance or specifications section.

The manual may list:

- Recommended battery group size

- Minimum Cold Cranking Amps (CCA) requirement

- Weight specifications for the factory-installed battery

- Special handling considerations based on weight

If you’ve misplaced your owner’s manual, many manufacturers now provide digital versions online that can be accessed by entering your vehicle’s identification number (VIN).

Heavier vs. Lighter Batteries: Making the Right Choice

Selecting between heavier traditional batteries and lighter modern alternatives involves understanding the trade-offs and benefits of each option.

Energy Density vs. Total Weight

The key metric when evaluating battery weight efficiency is energy density – the amount of power stored per unit of weight. Higher energy density means more power without proportionally increasing weight.

Traditional lead-acid batteries have relatively low energy density, storing approximately 30-40 watt-hours per kilogram. By comparison, modern lithium-ion batteries achieve 150-200 watt-hours per kilogram, representing a dramatic improvement in energy-to-weight ratio.

This means that while a heavier battery might store more total energy, a lighter battery with higher energy density could provide similar performance with less weight penalty. The ideal battery balances sufficient power capacity with optimal weight for your specific vehicle and usage patterns.

Considerations for Different Vehicle Types

Different vehicles have unique battery requirements based on their design, usage, and electrical demands:

- Standard Commuter Cars: Traditional lead-acid batteries typically provide sufficient power while keeping costs reasonable

- Performance Vehicles: Lightweight lithium batteries offer performance advantages through weight reduction

- Off-Road Vehicles: Heavy-duty batteries with reinforced construction withstand vibration and rough conditions

- Luxury Vehicles: AGM batteries support sophisticated electrical systems with stable power delivery

- Commercial Vehicles: High-capacity, durable batteries handle extensive use and multiple accessories

Your driving habits also influence the ideal battery choice. For vehicles that frequently make short trips, a more robust battery may be beneficial, while highway cruisers might prioritize weight savings for efficiency. Vade Battery’s vehicle-specific selector tool can help identify the optimal battery for your particular vehicle and usage pattern.

Future Trends in Battery Weight Technology

As we progress through 2025, several emerging technologies promise to further reduce battery weight while improving performance:

- Solid-state batteries eliminate liquid electrolytes, reducing weight while increasing energy density

- Silicon-anode technology boosts capacity without proportional weight increases

- Structural battery designs integrate battery components into vehicle structure, effectively eliminating separate battery weight

- Nano-material advancements improve conductivity and reduce the amount of material needed

These innovations suggest that battery weights will continue to decrease while performance improves. By 2030, experts predict automotive batteries could weigh 30-40% less than comparable models from 2020 while delivering superior performance and longevity.

Practical Tips for Battery Handling and Maintenance

Battery weight directly impacts how you should handle, install, and maintain this essential component.

Safe Handling Based on Weight

Due to their substantial weight, batteries require proper handling techniques to prevent injury and damage:

- Use proper lifting technique: Lift with your legs, not your back, keeping the battery close to your body

- Employ appropriate tools: Battery carriers provide secure grips and distribute weight evenly

- Get assistance when needed: Don’t hesitate to ask for help with particularly heavy batteries

- Secure during transport: Prevent shifting during transportation to avoid damage or acid leaks

For batteries exceeding 40 pounds, it’s advisable to use mechanical assistance or get help from another person during installation or removal. Many auto parts stores offer free installation with purchase, which can be valuable for handling heavier batteries.

Weight-Related Maintenance Considerations

Battery weight can affect maintenance requirements in several ways:

- Mounting security: Heavier batteries require secure mounting to prevent movement during driving

- Terminal strain: Extra weight can increase strain on terminals and cables if not properly supported

- Shelf placement: Store heavier batteries on lower shelves to prevent falling hazards

- Charging systems: Vehicle charging systems must be capable of maintaining heavier batteries

Regular maintenance becomes even more important with heavier batteries, as their weight can accelerate wear on mounting hardware and connection points. Inspect these components regularly for signs of stress or deterioration. For comprehensive maintenance guides specific to your battery type, visit Vade Battery’s maintenance guide section.

Conclusion

Car battery weight is a critical yet often overlooked specification that directly impacts vehicle performance, handling, and efficiency. As automotive technology advances through 2025, manufacturers continue developing lighter, more energy-dense battery solutions that maintain or improve performance while reducing weight penalties.

The ideal battery balances weight considerations with your vehicle’s specific requirements—from traditional lead-acid batteries (30-50 pounds) to advanced lithium alternatives (10-20 pounds). Focus on finding the right combination of weight, capacity, and durability for your driving habits and vehicle specifications.

Ready to upgrade your vehicle’s battery? Use our interactive Battery Selector Tool to find the perfect weight-optimized battery for your specific make and model, or contact our battery specialists for personalized recommendations based on your unique requirements.