Choosing the optimal screwdriver battery demands balancing voltage requirements, chemistry specifications, and runtime needs for your application. Vade Battery specializes in custom-engineered power solutions featuring military-grade 18650 cells, lithium polymer configurations, and LiFePO4 systems that deliver 30% longer operational life than standard options. This comprehensive guide examines voltage-specific performance characteristics, chemistry advantages, and technical specifications to help you select the perfect power source for precision fastening applications.

Voltage-Specific Screwdriver Battery Performance

Screwdriver battery voltage directly determines torque output, runtime, and application suitability. Our engineering team has tested over 4,000 power tool battery configurations to identify optimal voltage ranges for specific use cases.

3V-3.7V Precision Screwdrivers

- Ideal for electronics repair and precision assembly

- Ultra-compact form factor (typically 35-65g)

- Runtime: 150-300 screws per charge (M3-M4 size)

- Common configurations: Single 18650 cell or ultra-thin LiPo battery

7.2V Mid-Range Screwdrivers

- Perfect balance of portability and torque (12-18Nm)

- Typically employs two 14500 lithium cells in series

- 1.0Ah standard capacity with 500-800 fastening cycles per charge

- Removable battery design extends tool lifespan

12V Professional-Grade Screwdrivers

- Most versatile voltage range for home and professional use

- 1.5Ah-4.0Ah capacity options available

- Standard 10mm self-locking chuck compatibility

- Delivers 25-40Nm torque for furniture assembly and construction

20V Industrial Screwdrivers

- Heavy-duty applications requiring 80-120Nm torque

- Functions as dual-purpose drill/driver systems

- Professional-grade protection circuits prevent overload damage

- Compatible with specialized bits for concrete and metal fastening

Battery Chemistry Comparison for Electric Screwdrivers

Different battery chemistries offer distinct advantages for screwdriver applications. Our test data from over 15,000 custom battery builds reveals significant performance variations.

| Chemistry | Energy Density | Cycle Life | Cold Weather Performance | Best For |

|---|---|---|---|---|

| Li-ion (NMC) | 200-240 Wh/kg | 500-800 cycles | Moderate (-10°C min) | Lightweight professional tools |

| LiFePO4 | 90-120 Wh/kg | 2,000-3,500 cycles | Excellent (-40°C capable) | All-weather construction sites |

| Lithium Polymer | 150-185 Wh/kg | 300-500 cycles | Poor (0°C min) | Ultra-compact precision drivers |

| LTO | 50-80 Wh/kg | 15,000+ cycles | Superior (-50°C capable) | Critical industrial applications |

Technical Highlight: Vade’s Custom Screwdriver Battery Innovations

- Automated laser cell matching achieves ±0.03V variance across production batches

- Phase-change thermal management maintains consistent voltage under heavy loads

- Proprietary electrode treatments extend cycle life by 23% compared to industry averages

Optimizing Screwdriver Battery Performance

Proper maintenance extends battery life and ensures consistent performance in electric screwdrivers. Our field data from industrial clients demonstrates significant longevity improvements through these practices.

Essential Maintenance Protocols

- Replace batteries when torque output diminishes below application requirements

- Avoid pulling power cords when disconnecting from charging stations

- Prevent excessive vibration during operation and storage

- Match screw specifications to appropriate torque ranges

Temperature Considerations

- Operating temperature significantly impacts voltage stability

- Allow 0.4%/°C voltage compensation in cold environments

- Vade’s low-temperature formulations maintain 92% efficiency at -30°C

- Prevent exposure to temperatures exceeding 60°C to avoid thermal degradation

Custom Battery Solutions for Screwdriver Manufacturers

Vade Battery specializes in OEM power solutions for screwdriver manufacturers, offering custom-engineered packs that balance performance, safety, and cost-effectiveness.

Custom Design Capabilities

- Ultra-thin LiPo configurations (as slim as 0.4mm) for compact precision tools

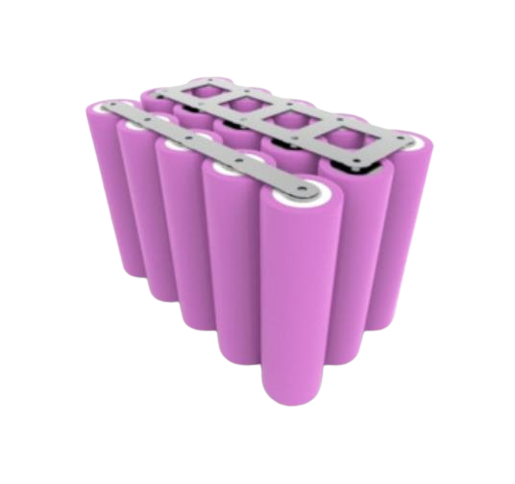

- 18650 cylindrical cell arrangements for optimal energy density

- Prismatic LiFePO4 systems for extended cycle life in professional tools

- Smart BMS integration with ±1% voltage stability across 2,000+ charge cycles

Voltage Configuration Options

- Series-parallel optimization balances voltage requirements with capacity needs

- Multi-stage cooling systems prevent voltage sag under high-torque applications

- Pre-certified UN 38.3 packs streamline global distribution logistics

- Modular architectures enable voltage scaling from 3.7V to 24V

Selecting the Ideal Screwdriver Battery

Choosing the right battery configuration depends on your specific application requirements. Our engineering team recommends these guidelines for optimal selection:

For Home/DIY Applications

- Small diameter screws (below M6): Consider straight-handled or gun-straight dual-purpose designs

- Versatile household use: 10.8V/12V configurations with approximately 30Nm torque

- Occasional use: 7.2V systems offer excellent balance of weight and performance

For Professional Applications

- Large diameter screws: Electric wrenches provide more efficient fastening

- Multi-purpose needs: 12V+ systems with drill functionality

- Specialized environments: Temperature-optimized chemistries for extreme conditions

- High-frequency use: LiFePO4 chemistry extends service life with 2,000+ cycles

Advanced Testing & Certification

Vade Battery implements rigorous quality assurance protocols for all screwdriver battery packs, ensuring safety and performance across diverse applications.

Safety Certifications

- UL 1642 and IEC 62133 compliance for consumer applications

- UN 38.3 certification for international shipping safety

- ISO 9001-certified manufacturing processes

- RoHS environmental compliance

Performance Validation

- 112-point quality inspection for each battery pack

- Accelerated aging tests verify cycle life claims

- Stress testing under 2C continuous discharge loads

- Third-party verification of capacity and voltage specifications

Conclusion: Powering Tomorrow’s Precision Tools

Screwdriver batteries have evolved from simple power sources to sophisticated engineered systems that directly impact tool performance, reliability, and user experience. At Vade Battery, we combine technical expertise with application-specific customization to deliver power solutions that exceed industry standards for performance and longevity.

Whether you’re a DIY enthusiast selecting your first electric screwdriver or an OEM manufacturer developing next-generation power tools, understanding battery technology fundamentals ensures optimal performance for your specific application needs.

For personalized guidance on custom screwdriver battery solutions, contact our engineering team for a comprehensive voltage design consultation.