Understanding the roles of anodes and cathodes is critical for anyone working with battery-powered systems. At Vade Battery, we engineer custom lithium-ion battery packs with precisely optimized electrodes to meet diverse performance requirements. Let’s break down how these components function and why their design impacts your application’s success.

What Are Battery Anodes and Cathodes?

Defining the Electrodes

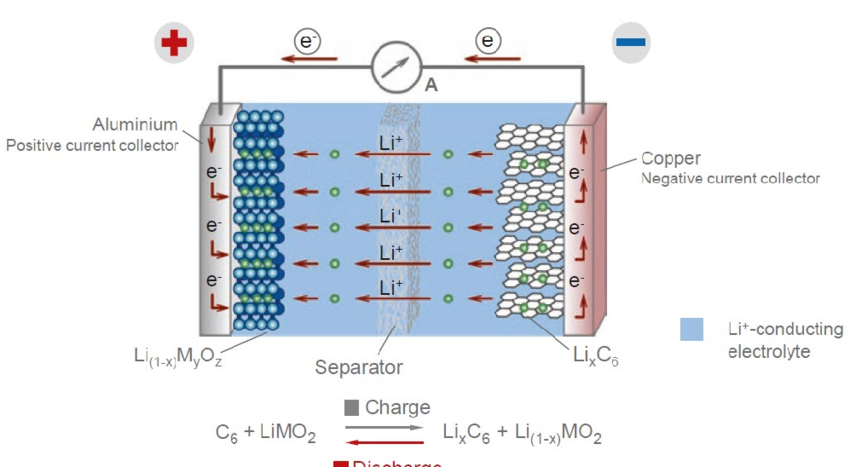

Anodes and cathodes are the two electrodes responsible for facilitating electrochemical reactions in batteries. The anode (negative electrode) releases electrons during discharge, while the cathode (positive electrode) absorbs them. Together, they enable energy storage and release through controlled ion movement.

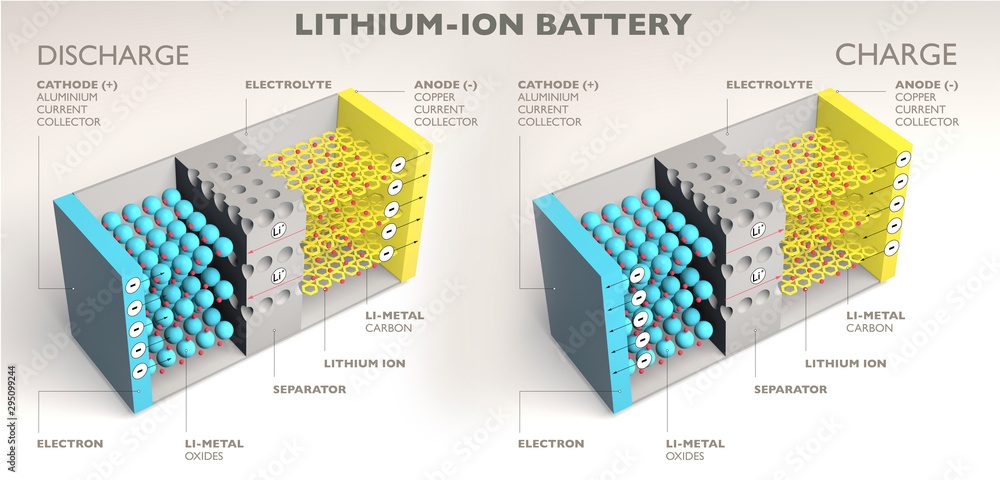

Role in Charge and Discharge Cycles

During discharge, lithium ions flow from the anode to the cathode through the electrolyte, generating electrical current. When charging, this process reverses: ions return to the anode, restoring energy storage capacity. Vade Battery’s proprietary electrode formulations maximize ion mobility, ensuring faster charging and higher energy retention. For applications requiring extreme temperature resilience, our ultra-low-temperature Li-ion batteries leverage advanced cathode materials to maintain performance in sub-zero environments.

Importance in Battery Design

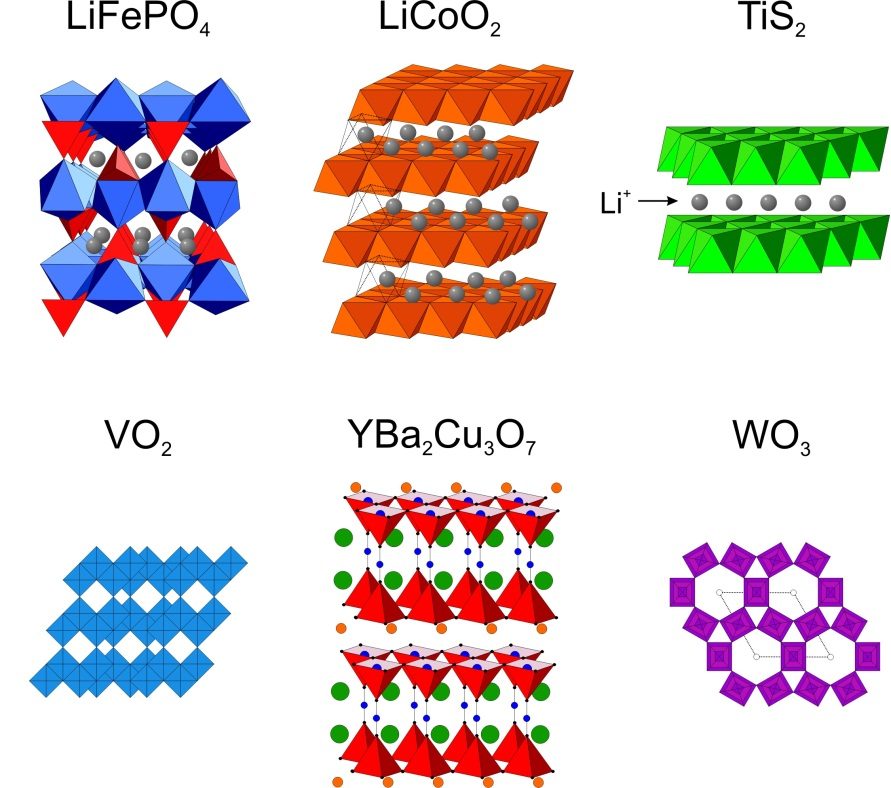

Electrode composition directly determines a battery’s energy density, lifespan, and safety. For example, our custom LiFePO4 battery packs use cathodes with enhanced ionic conductivity to balance power output and thermal stability.

Materials Used in Battery Electrodes

Cathode Materials

Modern lithium-ion batteries primarily use lithium iron phosphate (LiFePO4) or nickel manganese cobalt oxide (NMC) cathodes. LiFePO4 offers superior thermal stability and longevity, making it ideal for industrial applications, while NMC provides higher energy density for compact devices like those in our 18650 battery series.

Anode Materials

Graphite remains the standard anode material due to its layered structure, which efficiently hosts lithium ions. Vade Battery also integrates silicon-graphite composites in select high-capacity 18650 battery cells, boosting energy storage by up to 20%.

Material Selection Criteria

Choosing electrode materials involves balancing energy needs, cost, and safety. Our engineers prioritize UN 38.3-certified materials to meet international safety standards, particularly for applications like medical devices or aerospace systems.

How Electrodes Work in a Battery

Electron Flow During Discharge

When a battery powers a device, electrons exit the anode, travel through the external circuit, and re-enter the cathode. This flow creates usable electricity. The electrolyte ensures ions—not electrons—move internally, preventing short circuits.

Ion Movement in the Electrolyte

Lithium ions shuttle between electrodes through a liquid or solid electrolyte. Vade Battery’s custom lithium polymer batteries use advanced gel electrolytes to minimize leakage risks, even in high-vibration environments.

Impact of Electrode Design on Performance

Thicker electrodes increase energy capacity but reduce power output. For rapid-drain applications like power tools, we optimize electrode porosity and conductivity to deliver instant high-current output without compromising cycle life. Learn how we tailor these parameters in our custom lithium battery design process.

Manufacturing Anodes and Cathodes

Material Synthesis

Cathode powders like LiFePO4 are synthesized under precise temperatures to achieve uniform crystal structures. Anode materials undergo carbonization to enhance conductivity.

Electrode Fabrication

Slurries containing active materials, binders, and solvents are coated onto copper (anode) or aluminum (cathode) foils. After drying, electrodes are calendared to precise thicknesses—a process critical for ensuring consistent performance in our modular 24V/48V battery packs.

Quality Control

Vade Battery employs laser microscopy and X-ray diffraction to verify electrode homogeneity. This rigor ensures every custom LiFePO4 battery pack meets strict capacity and safety benchmarks.

Identifying Anodes and Cathodes in Batteries

Physical Markings

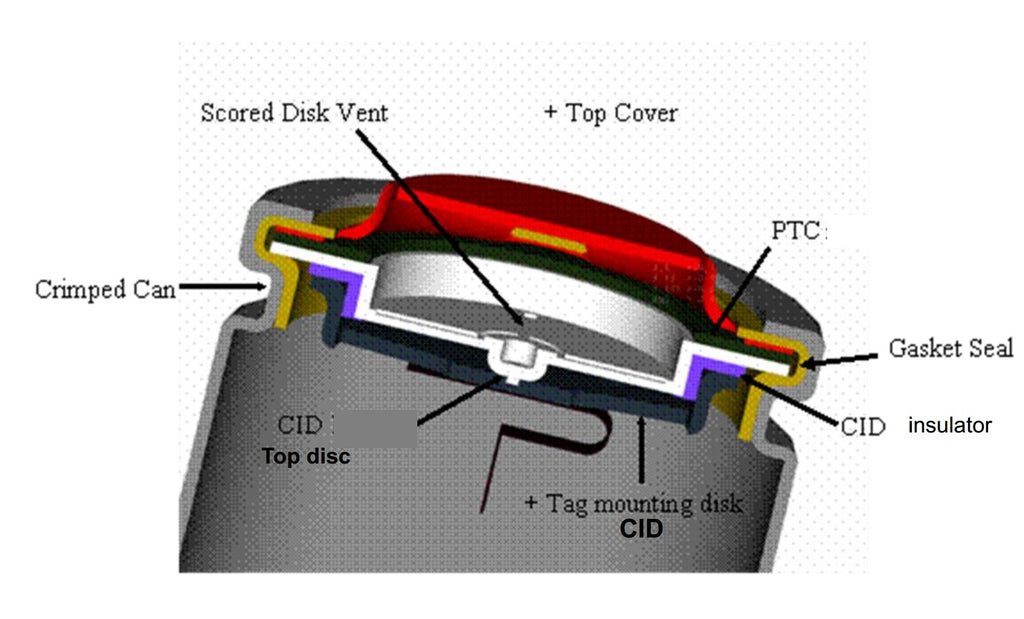

Most batteries label terminals with “+” (cathode) and “–” (anode). In cylindrical cells like 18650s, the flat end is typically the cathode.

Voltage Testing

A multimeter can confirm polarity: the cathode will show a higher potential relative to the anode.

Why Electrode Engineering Matters for Your Application

Safety Enhancements

By using thermally stable LiFePO4 cathodes, Vade Battery’s industrial-grade battery systems mitigate thermal runaway risks, even in high-temperature environments.

Cost Optimization

Graphite anodes offer a cost-effective solution for consumer electronics, while silicon blends extend lifespan for premium applications like our 72V golf cart batteries.

Custom Solutions

Whether you need a 48V industrial battery pack with extreme cycle durability or a lightweight polymer pack for drones, our electrode engineering tailors performance to your exact needs.

Partner with Vade Battery for Precision-Engineered Power

At Vade Battery, we combine advanced electrode materials with rigorous manufacturing protocols to deliver reliable, high-efficiency battery solutions. From concept to production, our team optimizes every aspect of anode and cathode design to meet your technical and budgetary requirements.

Explore our custom lithium-ion battery design process or contact our engineering team to discuss your project’s unique power needs.