Understanding TPMS Battery Technology

Tire Pressure Monitoring System (TPMS) batteries are specialized power sources that enable real-time monitoring of tire pressure conditions, providing critical safety alerts to prevent accidents caused by tire failures. These compact lithium cells power the sensors that continuously transmit pressure and temperature data to your vehicle’s central monitoring system, offering an essential early warning system for potentially dangerous tire conditions.

Key TPMS Battery Functions:

- Power wireless pressure sensors inside each tire

- Enable real-time data transmission via 315/434 MHz frequencies

- Maintain operational stability across extreme temperature ranges (-40°C to 125°C)

- Support precision measurement with ±1% full-scale accuracy

Critical Safety Role of TPMS Battery Performance

Tire pressure failures remain among the leading causes of traffic accidents, particularly under high-speed, high-temperature, and heavy-load conditions. A properly functioning TPMS battery ensures continuous monitoring that prevents:

- Increased fuel consumption from underinflated tires

- Premature tire wear and reduced tire lifespan

- Compromised vehicle handling and braking distances

- Catastrophic blowout risks during highway driving

Studies show that properly functioning TPMS systems reduce tire-related accidents by up to 56%, making the reliability of the battery component a critical safety factor.

Direct vs. Indirect TPMS Battery Requirements

Direct TPMS Technology

Direct TPMS utilizes dedicated pressure sensors mounted inside each tire, requiring specialized battery characteristics:

- Battery Type: 3V lithium cells (typically CR1632, CR2032, or CR2450)

- Expected Lifespan: 7-10 years under optimal conditions

- Temperature Tolerance: Must function reliably from -40°C to 125°C

- Transmission Capacity: Supports continuous or interval-based data transmission

Indirect TPMS Considerations

Indirect systems leverage ABS wheel speed sensors to detect rotational differences indicating pressure changes:

- System Integration: Often integrated with vehicle’s primary electrical system

- Supplementary Battery: May include backup power source for specific monitoring functions

- Calibration Requirements: Requires periodic recalibration after tire rotation or replacement

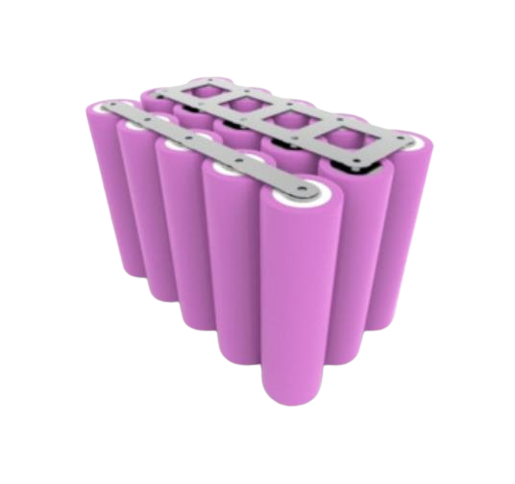

Vade Battery’s Advanced TPMS Solutions

High-Performance Lithium Technology

Vade Battery offers custom-engineered TPMS battery solutions featuring:

- 560mAh capacity in compact CR-series form factors

- Automotive-grade lithium chemistry with UN 38.3 certification

- Vibration-resistant construction maintaining airtight seals under 250kPa fluctuations

- Proprietary ASIC technology enabling automatic power management

Technical Advantages:

- Low self-discharge rate (<2% annually) for extended shelf life

- Smart sleep mode activation during vehicle stationary periods

- 40% reduced energy consumption compared to conventional TPMS batteries

- Stable voltage output across entire temperature operating range

Installation and Maintenance Considerations

Professional Installation Recommended

TPMS battery replacement typically requires specialized tools and proper sensor recalibration:

- Trained technicians ensure proper sensor sealing and pressure integrity

- Professional diagnostic equipment confirms proper system communication

- Correct initialization procedures prevent false warning lights

Optimizing Battery Lifespan

Maximize your TPMS battery performance through:

- Regular tire pressure checks to minimize transmission frequency

- Proper inflation maintenance reducing sensor activation cycles

- Seasonal tire changeovers with professional sensor checks

Technical Specifications for Vehicle Compatibility

| Vehicle Type | Recommended Battery | Communication Protocol | Expected Lifespan |

|---|---|---|---|

| Passenger Cars | CR2032 (560mAh) | 315MHz (US) / 434MHz (EU) | 7-9 years |

| Light Trucks | CR2450 (620mAh) | 315MHz (US) / 434MHz (EU) | 6-8 years |

| Commercial Vehicles | Custom Pack (900mAh+) | 315MHz (US) / 434MHz (EU) | 5-7 years |

For specific TPMS battery requirements matching your vehicle’s make and model, contact Vade Battery’s technical support team for customized recommendations that ensure optimal performance and safety.