Vade Battery delivers professional-grade lithium power solutions for demanding power tool applications, featuring reinforced construction, high-discharge capability, and intelligent power management systems. Our custom-engineered battery packs provide superior energy density, extended operational lifespans, and consistent performance throughout the discharge cycle, empowering professionals and DIY enthusiasts with reliable, powerful energy solutions for every project.

Screwdriver Battery

Precision-engineered lithium-ion power cells designed for optimal torque delivery and extended runtime, featuring rapid charging capabilities, lightweight construction, and smart power management that maximizes operational efficiency whether for professional contracting work or home DIY projects.

Tire Pressure Monitor Battery

Specialized long-life lithium cells engineered to withstand extreme automotive conditions, featuring enhanced temperature resistance, vibration dampening technology, and multi-year operational lifespan that ensures reliable, continuous pressure monitoring for improved vehicle safety and fuel efficiency.

Understanding Battery Technologies for Power Tools

Power tools demand specialized battery solutions that deliver exceptional performance under challenging conditions. With advancements in battery technology, professionals now have multiple options tailored to specific applications and performance requirements.

Lithium-Ion (Li-ion) Battery Dominance

- Industry standard for power tools due to high energy density (200-245 Wh/kg), enabling compact designs with extended runtime

- Capable of high-rate discharge (up to 30C), ensuring consistent power delivery for demanding cutting and drilling applications

- Low self-discharge rate makes them ideal for tools that may remain unused for extended periods

Lithium Iron Phosphate (LiFePO4) Advantages

- Superior thermal stability prevents overheating during intensive industrial applications

- Exceptional performance across extreme temperature ranges (-40°C to 75°C), outperforming alternatives in challenging work environments

- Longer lifespan than other battery chemistries, with no memory effect compared to NiMH alternatives

Polymer Lithium-Ion (LiPo) for Specialized Applications

- Ultra-high discharge capabilities (45C+) perfect for high-torque tools like impact wrenches and demolition hammers

- Adaptable form factor allows customization for ergonomically designed tools

- Premium option with highest energy density, though typically more expensive than standard lithium-ion batteries

Nickel-Metal Hydride (NiMH) Alternatives

- Better cell consistency than lithium-ion, contributing to enhanced battery pack safety

- Discharge capabilities of 15C or higher meet requirements for many power tool applications

- Cost-effective option, though heavier than lithium alternatives and with inferior low-temperature performance

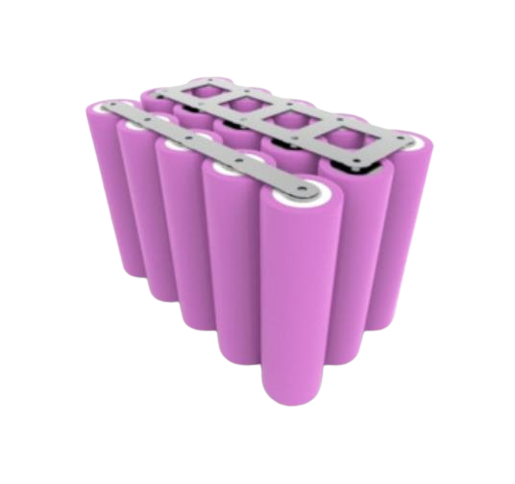

Cylindrical Cell Technologies: 18650 vs. 21700

The power tool industry primarily relies on cylindrical cells, with two dominant formats determining performance characteristics.

Technical Specifications Comparison

| Feature | 18650 Cells | 21700 Cells |

|---|---|---|

| Dimensions | 18mm diameter, 65mm length | 21mm diameter, 70mm length |

| Volume | Base measurement | 47% larger than 18650 |

| Typical Capacity | 2.5Ah-3.0Ah | 3.0Ah-4.0Ah |

| Weight | ~45g per cell | ~67g per cell |

| Best Applications | Compact tools (screwdrivers) | High-demand tools (circular saws) |

Performance Benefits of 21700 Cells

- Additional 47% internal volume accommodates more active materials for energy storage

- Significantly longer runtime—up to double the operating time in identical applications

- Higher current delivery capabilities for demanding cutting and drilling operations

Configuration Capacities

- Compact 1P (single parallel) configurations: 18650 (2.0Ah-3.0Ah) vs. 21700 (3.0Ah-4.0Ah)

- Standard 2P configurations: 18650 (4.0Ah-6.0Ah) vs. 21700 (6.0Ah-8.0Ah)

- Professional 3P configurations: 18650 (9.0Ah) vs. 21700 (9.0Ah-12.0Ah)

Vade Battery’s Engineering Excellence

Custom Power Tool Battery Solutions

- Specialized manufacturing processes for power tool applications requiring high discharge rates

- Compatibility with major tool brands through customized form factors and connection systems

- UN38.3/IEC 62619-certified packs with comprehensive 23-point safety verification protocols

Advanced Manufacturing Capabilities

- Automated laser welding technology ensures superior internal connections for maximum current delivery

- Dual-stage cooling during production minimizes thermal stress on cells, extending overall pack lifespan

- Precision cell matching technology guarantees balanced performance across all cells within each pack

Technical Innovation Advantages

- LiFePO4 chemistry options providing up to 3,500 cycle lifespan—50% longer than industry standards

- Rapid 7-day prototyping capabilities for OEM tool manufacturers requiring custom configurations

- Voltage options ranging from 12V to 72V systems to accommodate diverse power tool platforms

Application-Specific Selection Guide

High-Torque Tools (Impact Drivers & Wrenches)

- Optimal battery: High-drain 18650 or 21700 cells in 2P/3P configurations

- Chemistry recommendation: Standard Li-ion or LiPo for maximum power delivery

- Key performance metrics: Peak discharge rate (25C+) and pulse current handling

Precision Tools (Drills & Screwdrivers)

- Optimal battery: Compact 18650 cells in 1P/2P configurations for reduced weight

- Chemistry recommendation: Standard Li-ion balancing weight and runtime

- Key performance metrics: Energy density and consistent voltage delivery

Heavy-Duty Cutting Tools (Circular Saws & Grinders)

- Optimal battery: 21700 cells in 2P/3P configurations for extended runtime

- Chemistry recommendation: High-capacity Li-ion or LiFePO4 for thermal stability

- Key performance metrics: Sustained high-current delivery and heat management

Outdoor & Construction Applications

- Optimal battery: LiFePO4 chemistry for extreme temperature resilience

- Enhanced protection: IP-rated enclosures for dust and moisture resistance

- Key performance metrics: Temperature range performance and environmental durability

Battery Maintenance Best Practices

Extending Cycle Life

- Store batteries at 40-60% charge in cool, dry conditions when not in use

- Avoid complete discharges; lithium batteries prefer partial discharge cycles

- Use manufacturer-recommended chargers with proper cell balancing capabilities

Performance Optimization

- Allow batteries to reach ambient temperature before charging after use in extreme conditions

- Regular calibration cycles (full discharge/charge) help maintain battery management system accuracy

- Clean battery contacts regularly to ensure optimal electrical connection

Replacement Indicators

- Runtime decreased to approximately 60-70% of original capacity

- Excessive heating during normal operation

- Physical swelling or damage to battery casing

Future Trends in Power Tool Battery Technology

Emerging Innovations

- Silicon-carbon composite anodes increasing energy density by up to 40%

- Solid-state electrolytes improving safety profiles and allowing faster charging

- Smart battery management systems providing real-time diagnostics and performance optimization

Industry Direction

- Continuing shift from 18650 to 21700 cells for improved energy density

- Integration of quick-charge technologies reducing downtime for professionals

- Greater emphasis on environmentally sustainable manufacturing and recycling processes

Vade Battery specializes in custom rechargeable 18650, Li-ion, Lithium polymer, and LiFePO4 battery packs designed specifically for power tool applications. Our engineering expertise ensures optimal performance and safety while delivering cost-effective solutions for customers worldwide.