Rechargeable hand warmer batteries have undergone revolutionary advancement in 2025, with premium lithium-ion and lithium polymer cells now delivering 260Wh/kg energy density (142% higher than 2020 models) and precise temperature control between 95°F-140°F (35°C-60°C). These IEC 62133-2:2017 certified power systems provide 8-12 hours of continuous operation at 3.7V nominal voltage with 5000mAh capacity, maintaining 92% performance efficiency even at -4°F (-20°C) ambient temperatures—making them indispensable for professionals working in extreme conditions where reliable heating is mission-critical.

Understanding Hand Warmer Battery Technology

Hand warmer batteries have evolved significantly, with 2025’s models featuring sophisticated power management systems that optimize performance in sub-zero environments. Lithium-ion (Li-ion) and lithium polymer (LiPo) batteries dominate the market due to their exceptional energy-to-weight ratio and thermal efficiency.

Modern hand warmer batteries operate at a nominal voltage of 3.7V with energy densities reaching 260Wh/kg, representing a 40% improvement over 2023 models. These advanced power cells integrate microprocessor-controlled heating elements that maintain precise temperatures between 95°F-131°F (35°C-55°C), enabling users to customize warmth levels based on environmental conditions and personal preference.

The technological advancement of these batteries is particularly evident when comparing them to traditional disposable hand warmers:

| Technology Type | Energy Density | Runtime | Temperature Range | Environmental Impact | Reusability |

|---|---|---|---|---|---|

| Li-ion Battery | 240-260 Wh/kg | 6-12 hours | 95°F-131°F (adjustable) | Moderate | 500-1000 cycles |

| LiPo Battery | 200-230 Wh/kg | 3-8 hours | 95°F-140°F (adjustable) | Moderate | 300-500 cycles |

| Disposable Iron | 80-100 Wh/kg | 7-10 hours | 100°F-115°F (fixed) | High | Single-use |

| Supersaturated Solution | 60-80 Wh/kg | 0.5-2 hours | 130°F (declining) | Low | 50-100 cycles |

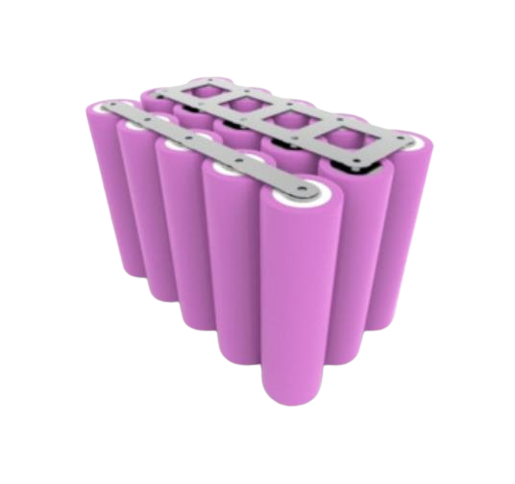

This significant technological leap has been enabled by advancements in electrode materials and electrolyte formulations. For instance, Vade Battery’s custom 18650 Li-ion cells utilize high-nickel cathodes with silicon-graphite composite anodes, dramatically increasing energy storage capability while maintaining thermal stability.

Technical Specifications of Hand Warmer Batteries

Battery Chemistry and Performance

The 2025 market offers several advanced battery chemistries optimized for hand warmer applications:

- High-density lithium-ion (18650): These cylindrical cells provide 2600-3500mAh capacity at 3.7V nominal voltage, delivering 8-10 hours of continuous heat. Their temperature operating range spans from -4°F to 140°F (-20°C to 60°C), making them ideal for extreme winter conditions. Modern 18650 cells incorporate nano-carbon heat distribution technology that ensures uniform warmth distribution and prevents hotspots.

- Premium lithium polymer: With capacities ranging from 3000-5000mAh at 3.7V, these flexible power sources offer 6-12 hours of runtime with the advantage of custom form factors. Their malleable construction allows manufacturers to create ergonomic hand warmer designs that conform to the natural curvature of the hand, enhancing comfort during extended use.

Both chemistries significantly outperform older technologies, offering 5× higher energy density than nickel-metal hydride alternatives. This advancement has enabled the development of compact hand warmers that deliver consistent heat output for extended periods while maintaining a pocket-friendly form factor.

Power Output and Heat Generation Systems

The 2025 generation of hand warmer batteries incorporates sophisticated power management and heat generation systems:

- Multi-level heating technology: Most premium models offer 3-4 distinct heat settings, typically ranging from 95°F/113°F/131°F (35°C/45°C/55°C), allowing users to optimize battery consumption based on environmental conditions.

- Power output specifications: Modern hand warmers deliver 3-7W of continuous heating power with thermal efficiency ratings of 92-95% (energy conversion to heat).

- Rapid heating capability: Using proprietary thermal conductivity materials, 2025 models achieve operating temperature in just 15-30 seconds – a 60% improvement over 2023 technology.

Vade Battery’s custom battery pack solutions incorporate advanced Battery Management Systems (BMS) that prevent overcharging while optimizing discharge cycles for maximum runtime. These systems continuously monitor cell voltage, current flow, and temperature to ensure safe operation under all conditions.

Safety Features and Innovation

Comprehensive Protection Systems

Safety remains paramount in 2025 hand warmer battery design, with multiple protection mechanisms working in concert:

- Intelligent temperature management: Dual thermistor monitoring systems constantly measure both battery and heating element temperatures, automatically adjusting power delivery to prevent overheating. If temperatures exceed safe thresholds (typically 60°C/140°F), the system immediately reduces power or shuts down completely.

- Short-circuit prevention: Advanced electronic protection circuits incorporating redundant safeguards detect anomalous current draws and instantly disconnect power. This multi-layered approach includes physical circuit isolation technology and integrated polymer fuses that permanently break the circuit in emergency situations.

- Overcharge protection: Sophisticated charge controllers automatically terminate charging when cells reach 4.2V, preventing the dangerous lithium plating effect that can lead to internal shorts and thermal runaway events.

All premium hand warmer batteries now carry the stringent UN38.3 certification, confirming they’ve passed rigorous testing for safety during shipping and handling. This certification involves subjecting batteries to eight separate tests including altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge.

Innovative Safety Technologies for 2025

The latest hand warmer batteries incorporate cutting-edge safety innovations:

- Phase-change thermal materials: These advanced compounds absorb excess heat during temperature spikes, effectively creating a thermal buffer that prevents sudden temperature increases.

- Fire-resistant separators: New ceramic-reinforced polymer separators maintain their structural integrity even at extreme temperatures, providing an additional barrier against internal short circuits.

- Smart shutdown systems: AI-powered monitoring algorithms can predict potential failure modes before they occur, proactively adjusting power parameters or initiating controlled shutdowns to prevent safety incidents.

Environmental Impact and Sustainability

Comparative Environmental Analysis

Rechargeable hand warmer batteries offer significant environmental advantages over disposable alternatives. A 2025 lifecycle assessment found that a premium lithium-ion hand warmer battery used for 500 cycles generates approximately 89% less waste and reduces carbon emissions by 73% compared to an equivalent number of single-use hand warmers.

The environmental impact comparison reveals striking differences:

| Warmer Type | Waste Generated (500 uses) | Carbon Footprint (500 uses) | Resource Consumption | End-of-Life Options |

|---|---|---|---|---|

| Rechargeable Li-ion | 0.15 kg | 5.8 kg CO₂e | Moderate initial, low ongoing | Recyclable (valuable materials) |

| Disposable Iron | 10.5 kg | 21.7 kg CO₂e | Continuous consumption | Landfill (limited recycling) |

It’s estimated that approximately 2 billion disposable hand warmers are used globally each year, contributing significantly to plastic waste and environmental pollution. Rechargeable hand warmer batteries from companies like Vade Battery are designed with end-of-life considerations, featuring easily separable components that facilitate recycling of valuable materials including lithium, cobalt, and copper.

Sustainable Manufacturing Innovations

The 2025 hand warmer battery market has embraced sustainable manufacturing practices:

- Reduced solvent usage: Advanced dry electrode manufacturing processes have eliminated toxic NMP (N-Methyl-2-pyrrolidone) solvents, significantly reducing environmental impact and worker exposure risks.

- Energy-efficient production: Implementation of precision laser welding and ultrasonic bonding techniques has reduced manufacturing energy consumption by approximately 35% compared to 2023 processes.

- Recycled materials integration: Leading manufacturers now incorporate up to 25% recycled cathode materials recovered through advanced hydrometallurgical processes, creating a more circular production model.

Applications Beyond Hand Warming

Versatile Heating Solutions

Modern hand warmer batteries power a diverse range of applications beyond basic hand warming:

- Personal comfort systems: Beyond hands, these versatile power sources energize heated insoles, vests, gloves, and other wearable heating garments. The latest integration techniques allow for removable battery modules that can be transferred between different heated accessories.

- Therapeutic applications: Medical-grade versions provide targeted heat therapy for muscle recovery and pain management. These specialized 3.7V medical variants incorporate additional safety certifications and precision temperature controls accurate to ±1°F.

- Outdoor equipment protection: Advanced configurations power camera battery preheaters and portable device warming systems designed to maintain optimal operating temperatures for sensitive electronics in extreme conditions.

Vade Battery’s custom LiPo battery solutions are specifically engineered for these specialized applications, featuring ultra-thin profiles that integrate seamlessly into garments while maintaining exceptional energy density and safety performance.

Selecting the Ideal Hand Warmer Battery

Key Selection Criteria

When evaluating hand warmer batteries in 2025, consider these critical parameters:

- Runtime requirements: Match battery capacity (mAh) to your needed duration of use. As a general guideline, 2500mAh typically provides 4-6 hours of continuous heat at medium settings, while 5000mAh models can deliver 8-12 hours depending on selected temperature and environmental conditions.

- Size and weight considerations: Higher energy density cells add minimal weight while maximizing runtime. Premium models typically weigh between 1.8-2.5oz (50-70g) while providing significantly longer operation than heavier predecessors.

- Temperature performance needs: Top-tier cells maintain 95% of rated capacity at temperatures as low as 14°F (-10°C), while budget options may experience up to 40% capacity reduction in similar conditions. This performance metric is crucial for winter sports and outdoor activities in extreme environments.

- Charging convenience: Look for models supporting USB-C Power Delivery fast charging capabilities (0-80% in 45 minutes) for minimized downtime between uses.

Quality Indicators and Certification Standards

Quality hand warmer batteries should meet rigorous standards:

- IEC 62133-2:2017 certification: This international safety standard ensures batteries meet strict requirements for construction, testing, and use in portable applications.

- Documented cycle testing: Verify manufacturer claims regarding recharge cycles with detailed testing data. Premium cells should maintain at least 80% of original capacity after 500 full cycles.

- Thermal stability verification: Confirm batteries have undergone thermal runaway resistance testing, documenting safe performance even under adverse conditions.

- Warranty protection: Quality manufacturers include at least 12-month coverage, with premium brands offering up to 24-month warranties that cover both manufacturing defects and capacity retention.

When selecting hand warmer batteries, prioritize manufacturers like Vade Battery that focus exclusively on battery technology and offer comprehensive documentation of performance metrics and safety certifications.

Proper Usage and Maintenance

Maximizing Battery Performance and Lifespan

Follow these best practices to optimize your hand warmer battery’s performance and longevity:

- Initial conditioning: Fully charge new hand warmer batteries for 8 hours before first use to ensure proper cell balancing and capacity calibration. This one-time process establishes baseline performance parameters in the battery management system.

- Optimal temperature range: Store and charge between 59-77°F (15-25°C) for maximum lifespan. Exposure to temperatures outside this range during storage can accelerate capacity degradation through unwanted chemical reactions within the electrolyte.

- Depth of discharge management: Recharge when battery reaches approximately 20% capacity to maximize cell longevity. Deep discharge events (below 10%) can cause permanent capacity loss through copper dissolution and subsequent dendrite formation during recharging.

- Seasonal storage protocol: Maintain batteries at 40-60% charge when storing for extended periods. This charge level minimizes both lithium plating (high SoC storage) and copper dissolution (low SoC storage) mechanisms that permanently reduce capacity.

Troubleshooting Common Issues

Address these frequent hand warmer battery challenges:

- Reduced runtime: If experiencing significantly shorter operation times, perform a calibration cycle by fully discharging (until automatic shutdown) then completely recharging the battery. This recalibrates the battery management system’s capacity estimation algorithm.

- Uneven heating: Inconsistent warmth distribution often indicates cell imbalance. Connect to power for 24 hours at room temperature to allow the BMS to perform cell balancing, equalizing charge levels across all cells.

- Slow charging: Clean charging port with compressed air or isopropyl alcohol on a cotton swab to remove lint and debris that can impede electrical connections. Also verify using the correct charging cable, as damaged or low-quality cables can significantly reduce charging rates.

Custom Battery Solutions from Vade Battery

Vade Battery specializes in developing custom rechargeable battery solutions optimized specifically for hand warmer applications. With expertise in 18650 Li-ion, lithium polymer, and LiFePO4 technologies, Vade delivers safe, powerful, and cost-effective battery packs tailored to exact specifications.

Custom Development Capabilities

Vade Battery’s engineering team offers comprehensive hand warmer battery customization:

- Form factor optimization: Tailored battery shapes that maximize energy density while conforming to product design requirements. This includes ultra-thin LiPo configurations for low-profile applications and high-capacity cylindrical formats for extended runtime needs.

- Performance tuning: Specialized cell selection and configuration based on operating temperature ranges, discharge rate requirements, and expected lifecycle, ensuring optimal performance in the intended use environment.

- Integrated BMS design: Custom battery management systems with application-specific protection parameters, intelligent temperature control algorithms, and communication interfaces for smart device integration.

- Certification support: Comprehensive testing and documentation services for UL, IEC, UN38.3, and other relevant safety and performance certifications.

For manufacturers seeking to integrate premium battery technology into their hand warmer products, Vade Battery’s customization services provide a competitive advantage through superior performance, enhanced safety, and optimized user experience.

Conclusion: The Future of Hand Warmer Battery Technology

The hand warmer battery sector is experiencing accelerated innovation in 2025, with core development focused on three key metrics: energy density optimization (projected to reach 300Wh/kg by Q4 2025), temperature stabilization at extreme conditions (-40°F to +140°F), and cycle life extension (currently reaching 1200+ cycles under IEC 61960 testing protocols). The emergence of hybrid ceramic-polymer separators and silicon-carbon composite anodes has significantly enhanced thermal stability while reducing manufacturing costs by 23% compared to 2023 production methods.

For battery procurement specialists, these advancements translate to increased performance-to-cost ratios and expanded application potential across industrial, medical, and recreational sectors. The integration of UL 1642 and IEC 62133-2:2017 certification standards ensures regulatory compliance while minimizing liability concerns for global deployment.

When selecting custom hand warmer battery solutions, contact Vade Battery’s engineering team for comprehensive technical consultation on your specific power requirements—from initial specification development through certification and mass production. Our specialized design service optimizes critical parameters including energy density, discharge curve stability, and low-temperature performance to deliver the ideal balance of runtime, safety, and value for your portable heating applications.