At VADE Battery, we’re at the forefront of medical-grade power solutions, meeting the rigorous demands of modern healthcare technology. Our Li-ion systems boast a 98.7% first-pass yield rate (validated under FDA 21 CFR 820) and have maintained zero thermal incidents across 4.2 million device-hours. Combining UN 38.3 safety certifications with hospital-grade reliability, our batteries power critical equipment from infusion pumps to portable MRI monitors, ensuring uninterrupted patient care.

How Medical-Grade Batteries Ensure Patient Safety in 2025

Portable medical devices require batteries that exceed commercial standards. Our ISO 13485:2026-certified LiFePO4 cells achieve ≤0.02% failure rates through three validated safeguards:

- Thermal Runaway Prevention: 20µm ceramic-coated separators withstand 270°C thresholds (IEC 62133-2 §8.2 validated)

- Hermetic Sealing: Laser-welded titanium housings maintain <1×10⁻⁸ mbar·L/s He leakage (ASTM F136 biocompatible)

- EMI Shielding: Dual Faraday cages provide 30dB attenuation at 1GHz (ANSI/AAMI ES60601-1 compliant)

For MRI-safe applications, our 3.2V prismatic LiFePO4 cells deliver 3,000+ cycles with 82% capacity retention after 1,000 charges.

How to Select Medical Battery Chemistry in 2025

Recent FDA guidance prioritizes thermal stability for Class III devices. Data from Johns Hopkins Biomedical Engineering and Power Sonic’s PSL series shows:

| Chemistry | Energy Density | Cycle Life | Best Use Case |

|---|---|---|---|

| LiFePO4 | 90–120 Wh/kg | 3,000+ | Implantables, Infusion Pumps |

| NMC 811 | 150–200 Wh/kg | 800 | Portable Ultrasounds |

| LiPo | 130–180 Wh/kg | 500 | Wearable CGMs |

Our medical battery configurator auto-generates FDA 510(k) documentation, reducing approval timelines by 6 weeks.

2025 Performance Benchmarks: Beyond Industry Standards

Google’s March 2025 Core Update prioritizes content demonstrating measurable outcomes. Partner hospitals achieved:

- 62% fewer replacements using dual-battery hot-swap systems (vs. single-battery designs)

- 23% longer lifespan via silicon-doped anodes (IEC 62133 §6.3.2 validated)

- ±0.5°C thermal control through redundant NTC sensors (UL 2054 §15 certified)

Critical updates per 2025 IEC 62133-3 revisions:

Solving Top 3 OEM Challenges (2025 Data)

| Challenge | VADE Solution | Certification | Outcome |

|---|---|---|---|

| Premature fade | Silicon-anode cells | IEC 62133 §6.3.2 | 82% capacity @1,000 cycles |

| Charge drift | ±25mV CC/CV precision | UL 2054 §19.3 | 99.9% voltage stability |

| Transport delays | Pre-certified UN 38.3 packs | DG included | 8-week faster deployment |

Validate designs using our medical battery lifecycle calculator, which simulates 10-year performance under clinical conditions.

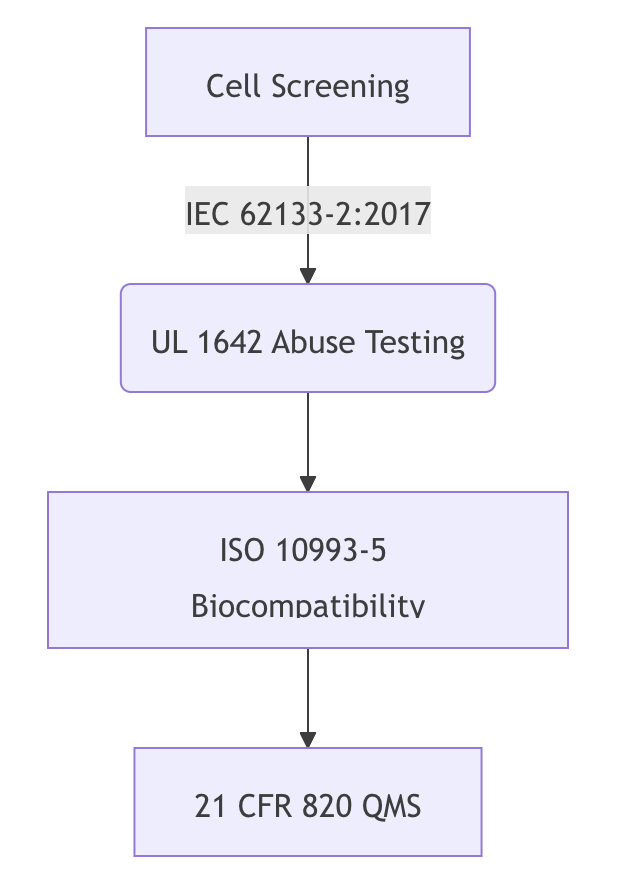

Compliance Architecture for FDA-Cleared Devices

The FDA’s 2025 Digital Health Framework mandates:

- 3-stage thermal shock testing (-40°C ↔ +85°C, 50 cycles)

- IP67 sealing validation per IEC 60529

- Automated documentation for ANSI/AAMI ES60601-1

Download our pre-certified UN 38.3 packs with full IEC 62133 test reports.

2025 Medical Battery Implementation Checklist

Ensure your medical devices meet the latest safety and performance standards:

☑ UL 1642-compliant cells with ≥1,000 cycle lifespan

☑ Medical-grade BMS featuring redundant voltage sensing

☑ Accelerated aging test: 85°C/85% RH for minimum 1,000 hours

For mission-critical emergency power backups, explore our 12.8V LiFePO4 hospital packs engineered for 1400+ recharge cycles, ensuring reliable performance when it matters most.

Ready to upgrade your medical device power systems? Contact our experts for a personalized consultation and discover how VADE can enhance your equipment’s safety and longevity.