Understanding battery specifications is crucial for selecting optimal power solutions across diverse applications. Modern energy storage systems require comprehension of both traditional metrics like Cold Cranking Amps (CCA) and emerging indicators such as C-rates and energy density. This comprehensive guide explores how these specifications translate to real-world performance, helping engineers, procurement specialists, and system designers make informed decisions when comparing lead-acid batteries with advanced lithium technologies.

Traditional vs. Modern Battery Rating Systems

Cold Cranking Amps (CCA) remains vital for cold climate applications, measuring a battery’s 30-second current output at 0°F (-18°C) without dropping below 7.2V. While lead-acid batteries lose 40-60% capacity in subzero conditions, our ultra-low-temperature LiFePO4 cells maintain 95% efficiency at -30°C through nickel-plated terminals and multi-layer insulation.

Three key cranking standards dictate battery selection:

| Metric | Temperature | Applications | Lead-Acid Range | Lithium Range |

|---|---|---|---|---|

| CCA | 0°F (-18°C) | Automotive | 600-800A | 800-1,200A |

| MCA | 32°F (0°C) | Marine | 800-1,000A | 1,000-1,500A |

| HCA | 80°F (27°C) | Desert climates | 700-900A | 900-1,200A |

Modern systems demand cycle depth compatibility – LiFePO4 withstands 3,500+ cycles at 100% Depth of Discharge (DoD) versus lead-acid’s 500 cycles at 50% DoD. Our dual battery system guide demonstrates how lithium’s deep-cycle capability revolutionizes energy storage.

Essential Performance Metrics for Lithium Batteries

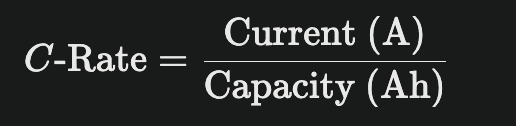

C-Rates quantify charge/discharge speeds relative to capacity:

A 100Ah battery discharges at 100A (1C) for 1 hour or 200A (2C) for 30 minutes. Our high-power 18650 cells deliver 20C rates – 96A bursts from 4.8Ah capacity – enabling 2.6-minute high-current applications.

Energy vs. Power Density creates critical tradeoffs:

- Energy Density (Wh/kg): Li-ion ≈ 250 Wh/kg vs LiFePO4 ≈ 160 Wh/kg

- Power Density: LiFePO4 maintains stable 1C-3C discharge vs Li-ion’s 0.5C-1C limits

VADE’s energy density calculator helps designers balance runtime and power needs.

Translating Specifications to Real-World Performance

Manufacturer datasheets often omit critical context:

- Cycle life claims without DoD specifications

- C-rate limits at various temperatures

- Internal resistance impacts (0.5mΩ LiFePO4 vs 5mΩ lead-acid)

Our BMS design guide details how smart battery management:

- Prevents thermal runaway through <2mV cell balancing

- Enables 48V systems with <3% voltage sag at 200A loads

- Extends lifespan via ±0.5% charge voltage regulation

Selecting the Right Battery Chemistry

18650 Format Breakdown:

| Chemistry | Energy Density | Cycle Life | Thermal Stability |

|---|---|---|---|

| Li-ion | 250 Wh/kg | 500 cycles | 150°C |

| LiFePO4 | 160 Wh/kg | 3,500+ cycles | 500°C |

| LiPo | 200 Wh/kg | 300 cycles | 100°C |

Cost Analysis (50kWh system):

| Parameter | Lead-Acid | LiFePO4 |

|---|---|---|

| Installations Needed | 6 | 1 |

| Total Cost | $78k | $23k |

| Cost/kWh/cycle | $0.42 | $0.15 |

As shown in our flooded vs LiFePO4 comparison, lithium achieves 280% lower lifetime costs despite higher upfront investment.

Industrial Case Study:

A Maui wind farm uses 11MW/4.3MWh LiFePO4 arrays for ramp-rate control, maintaining grid stability through 2,000+ charge cycles with <2% capacity loss.

The evolution from traditional lead-acid to lithium battery technologies represents a significant advancement in energy storage capabilities. By understanding the complete spectrum of battery specifications—from cold weather performance to cycle life, energy density, and thermal stability—stakeholders can select optimal solutions for their specific applications. As battery technology continues to evolve, maintaining updated knowledge of these metrics ensures systems are designed with the appropriate balance of performance, longevity, safety, and cost-effectiveness.