Choosing the right battery chemistry is critical for optimizing device performance, safety, and cost-efficiency. Lithium and alkaline batteries dominate modern applications, but their distinct chemical properties and performance metrics make them suited for vastly different use cases. At Vade Battery, we specialize in custom lithium solutions for industries ranging from aerospace to renewable energy, leveraging UN 38.3-certified cells and advanced BMS designs to ensure reliability in demanding environments.

This guide compares lithium and alkaline batteries across chemistry, performance, lifespan, and environmental impact, providing engineers and procurement teams with actionable insights for selecting optimal power sources. For foundational lithium battery concepts, explore our Lithium-Ion Battery Basics resource.

Core Chemistry Differences

Lithium Battery Composition

Lithium batteries utilize advanced electrochemical systems, with variations like lithium iron phosphate (LFP) and nickel manganese cobalt (NMC) dominating industrial applications. These batteries operate via lithium-ion movement between electrodes, enabling high energy transfer efficiency and stability. For instance, LFP cells excel in safety due to their thermally stable structure, while NMC variants prioritize energy density for compact devices like drones or medical equipment.

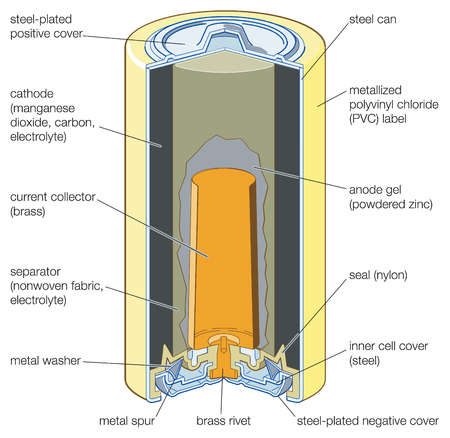

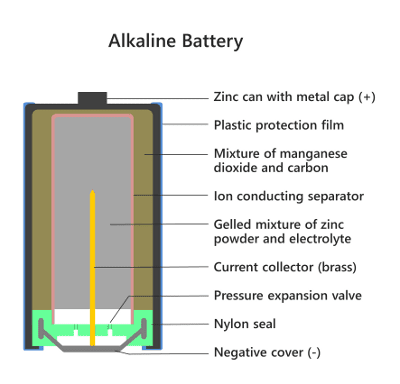

Alkaline Battery Composition

Alkaline batteries rely on a zinc-manganese dioxide reaction, using potassium hydroxide as the electrolyte. This chemistry supports single-use applications, such as remote controls or low-drain gadgets, but lacks the reusability or energy density of lithium systems. Their 1.5V nominal voltage remains steady during discharge, making them suitable for basic electronics but ineffective for high-power demands.

Performance Metrics

Energy Density and Efficiency

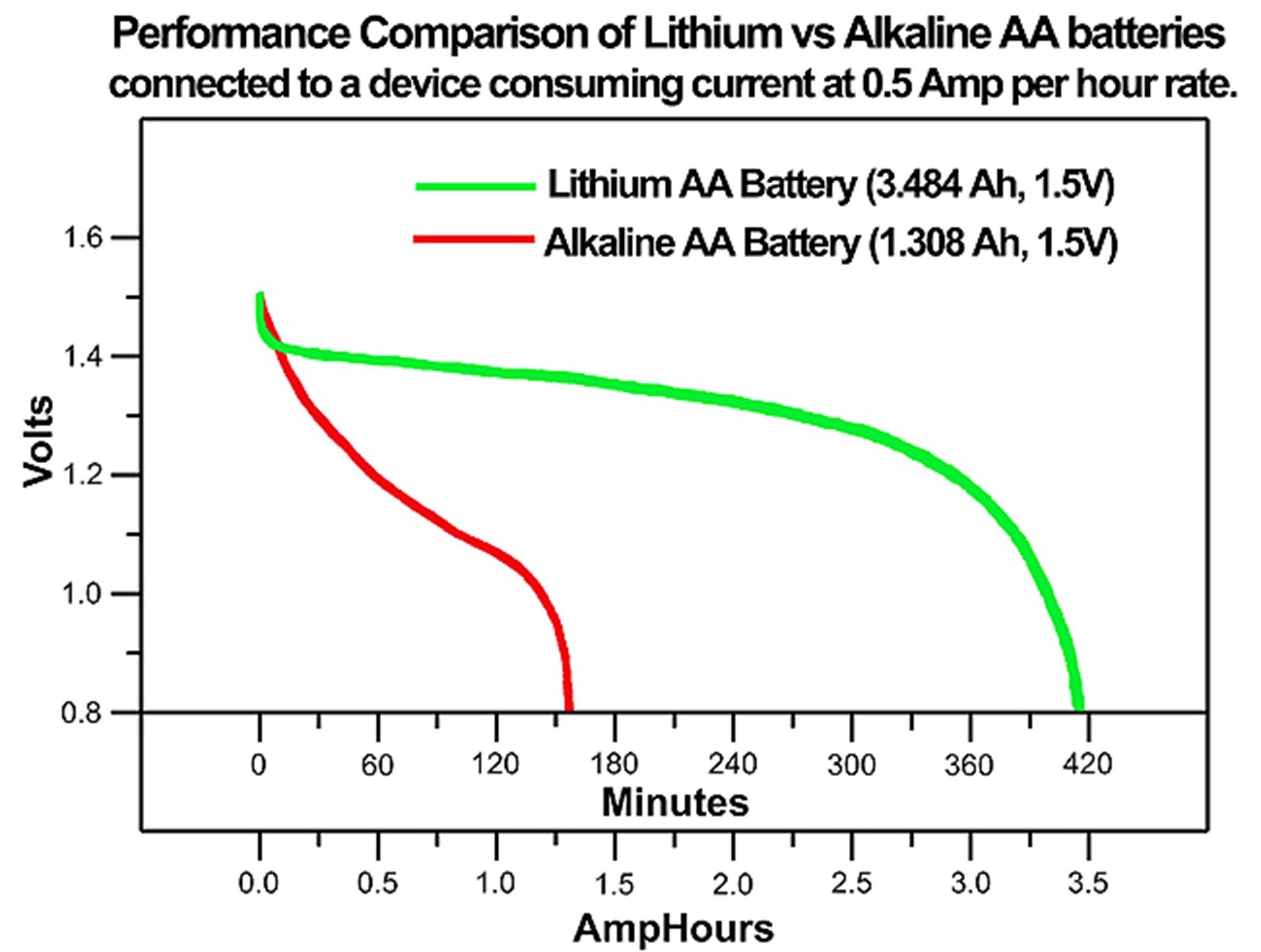

Lithium batteries deliver 200-265 Wh/kg, ideal for devices requiring prolonged runtime in minimal space, such as IoT sensors or wearable tech. In contrast, alkaline batteries provide 80-100 Wh/kg, limiting them to intermittent-use devices like wall clocks.

Self-Discharge and Shelf Life

Lithium batteries retain 90% charge after 1 year, outperforming alkaline variants, which lose 5-10% monthly. This makes lithium solutions preferable for emergency backup systems or seasonal equipment.

Discharge Rates and Temperature Tolerance

Lithium cells support continuous 20A+ discharge rates, critical for power tools or robotics. They also operate in -40°C to 60°C ranges, unlike alkaline batteries, which falter below freezing. Vade Battery’s Ultra-Low Temp Li-Ion Series extends this capability for Arctic research or military applications.

Voltage Profiles and Lifespan

Voltage Stability

Lithium-ion cells maintain a flat discharge curve (e.g., 3.7V nominal for NMC), ensuring stable power until depletion. Alkaline batteries gradually drop from 1.5V to 0.8V, causing performance dips in high-drain devices like digital cameras.

Cycle Life and Cost Efficiency

Lithium batteries endure 500-1,000 cycles, reducing long-term costs despite higher upfront pricing. Alkaline batteries are disposable, requiring frequent replacements that increase waste and operational expenses. For example, Vade’s 18650 Li-Ion Battery Packs offer 1,200+ cycles, ideal for commercial solar storage or EV conversions.

Cost Analysis and Long-Term Value

Upfront Costs vs. Lifetime Savings

Lithium batteries typically cost 2-4x more upfront than alkaline equivalents due to complex manufacturing and advanced materials. For example, a 48V lithium pack for solar storage may cost $500 compared to $200 for an alkaline-based system. However, lithium’s 500-1,200-cycle lifespan reduces replacement frequency, delivering 30-50% lower total cost of ownership (TCO) over a decade.

Alkaline batteries, priced at $0.50-$1 per AA cell, suit low-budget, short-term projects but become costly in high-drain applications like security systems, where monthly replacements add up. For a deeper cost breakdown, see our analysis: Why Are Lithium Batteries Expensive?.

| Metric | Lithium Batteries | Alkaline Batteries |

|---|---|---|

| Initial Cost (AA Cell) | $5 – $10 (rechargeable) | $0.50 – $1 (disposable) |

| Lifespan | 500–1,200 cycles | Single use |

| Cost Over 5 Years | ~$15 (with 1,000 cycles) | ~$50–$100 (50–100 replacements) |

| Cost per kWh | $150–$300 | $500–$1,000 |

| Environmental Cost | 95% recyclable, lower waste | 2% recycled, higher landfill impact |

Custom Solutions for Cost Optimization

Vade Battery’s custom lithium packs balance performance and budget by tailoring cell chemistry, capacity, and voltage. For instance, using LiFePO4 cells in industrial UPS systems reduces long-term costs by 40% compared to off-the-shelf alkaline alternatives.

Environmental Impact and Sustainability

Recyclability and Waste Reduction

Lithium batteries are 95% recyclable, with recovered materials like cobalt and nickel reused in new cells. Vade’s UN 38.3-certified packs comply with global safety and recycling standards, minimizing landfill waste. In contrast, single-use alkaline batteries contain corrosive electrolytes and heavy metals, with only 2% recycled globally due to high processing costs.

Carbon Footprint Comparison

While lithium production emits 20-40% more CO₂ initially, their extended lifespan offsets this through reduced manufacturing demand. Alkaline batteries generate 3x more emissions over 10 years due to constant mining, production, and disposal.

Choosing the Right Battery for Your Application

When to Use Lithium Batteries

Opt for lithium in:

- High-performance devices: Drones, medical equipment, or EV conversions requiring stable voltage and fast discharge.

- Extreme environments: Subzero industrial sensors or desert solar farms. Explore our ultra-low-temperature series for cold-climate solutions.

- Long-term deployments: IoT networks or telecom infrastructure where maintenance access is limited.

When to Use Alkaline Batteries

Alkaline remains practical for:

- Low-drain devices: Remote controls, wall clocks, or toys with intermittent usage.

- Short-term projects: Prototypes or temporary installations where upfront cost outweighs longevity.

Conclusion

Lithium batteries outperform alkaline in energy density, temperature resilience, and lifespan, making them ideal for mission-critical applications. However, alkaline’s low upfront cost suits disposable or low-power needs.

At Vade Battery, we engineer custom lithium solutions tailored to your voltage, capacity, and environmental requirements. Our expertise in BMS design and high-density cell integration ensures compliance with IEC 62133 and UN 38.3 standards, mitigating risks like thermal runaway or leakage.

For a personalized consultation, contact our engineering team or explore our LiFePO4 vs. Li-Ion comparison to refine your selection.