In battery-powered systems, watts define the backbone of energy efficiency, safety, and performance. Whether you’re designing a portable medical device, an electric vehicle, or a solar-powered boat, understanding watts—the unit measuring the rate of energy transfer—determines how effectively your system operates. At Vade Battery, we engineer custom lithium-ion and LiFePO4 battery packs that align with exact wattage requirements, ensuring optimal power delivery for applications ranging from milliwatt IoT sensors to multi-kilowatt industrial equipment.

This article breaks down the science of watts, their practical implications for engineers and product designers, and how Vade Battery’s solutions address challenges like heat management, circuit protection, and energy density. By the end, you’ll know how to calculate wattage, balance high- and low-power demands, and select battery systems that maximize cost-effectiveness without compromising safety.

What Are Watts in Electrical Systems?

Defining Power Measurement in Battery Systems

Watts (W) represent the rate of energy transfer or conversion in electrical systems. Named after James Watt, this unit quantifies how quickly a device consumes or produces energy. For battery-powered applications, understanding watts is critical for evaluating performance, efficiency, and compatibility. For example, a 60-watt light bulb uses 60 watts of power every second it’s illuminated. Higher wattage devices demand more energy, which directly impacts battery runtime and system design.

Understanding Milliwatts to Gigawatts

Watts are measured across scales to suit different applications:

- Milliwatts (mW): Used for small electronics like sensors or LED lighting.

- Kilowatts (kW): Common in household appliances (e.g., microwaves) and industrial machinery.

- Megawatts (MW): Applied to large-scale systems like electric vehicle charging stations or grid storage.

- Gigawatts (GW): Reserved for utility-scale power generation or massive industrial operations.

At Vade Battery, our custom lithium-ion battery packs are engineered to support devices ranging from milliwatt medical devices to kilowatt-level solar storage systems. For instance, our 18650 battery packs provide precise power delivery for applications requiring 3.6V to 72V configurations.

Practical Examples in Energy Consumption

Household devices often list both starting (surge) and running wattage. A refrigerator might require 1,200 watts at startup but only 800 watts during normal operation. This distinction is vital when designing battery systems to handle peak loads without overloading circuits.

How to Calculate and Measure Wattage

DC vs. AC Power Measurement

For direct current (DC) systems (common in batteries), wattage is calculated using the formula:

Watts (W) = Volts (V) × Amperes (A).

A 12V battery delivering 10A produces 120W. For alternating current (AC), the equation incorporates a power factor (PF): Watts = Volts × Amps × PF. This accounts for inefficiencies in energy conversion, critical for industrial equipment.

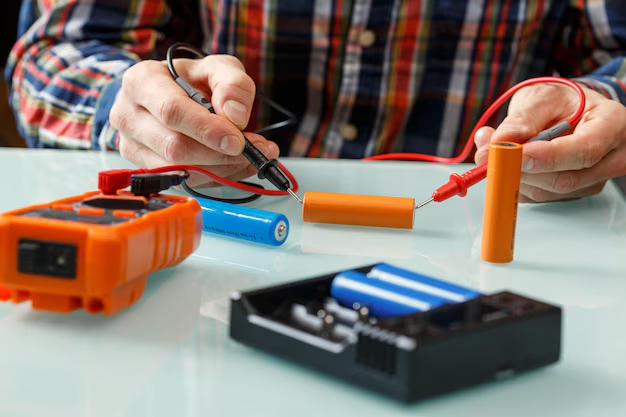

Using Multimeters for Real-World Applications

To measure wattage in a DC circuit:

- Use a multimeter to measure voltage across the battery terminals.

- Measure current flowing through the circuit.

- Multiply volts by amps to determine watts.

For precision, Vade Battery’s custom LiFePO4 battery packs include integrated battery management systems (BMS) that monitor real-time power metrics, ensuring safe operation within specified limits.

High vs. Low Wattage in Battery Applications

When High Wattage Matters

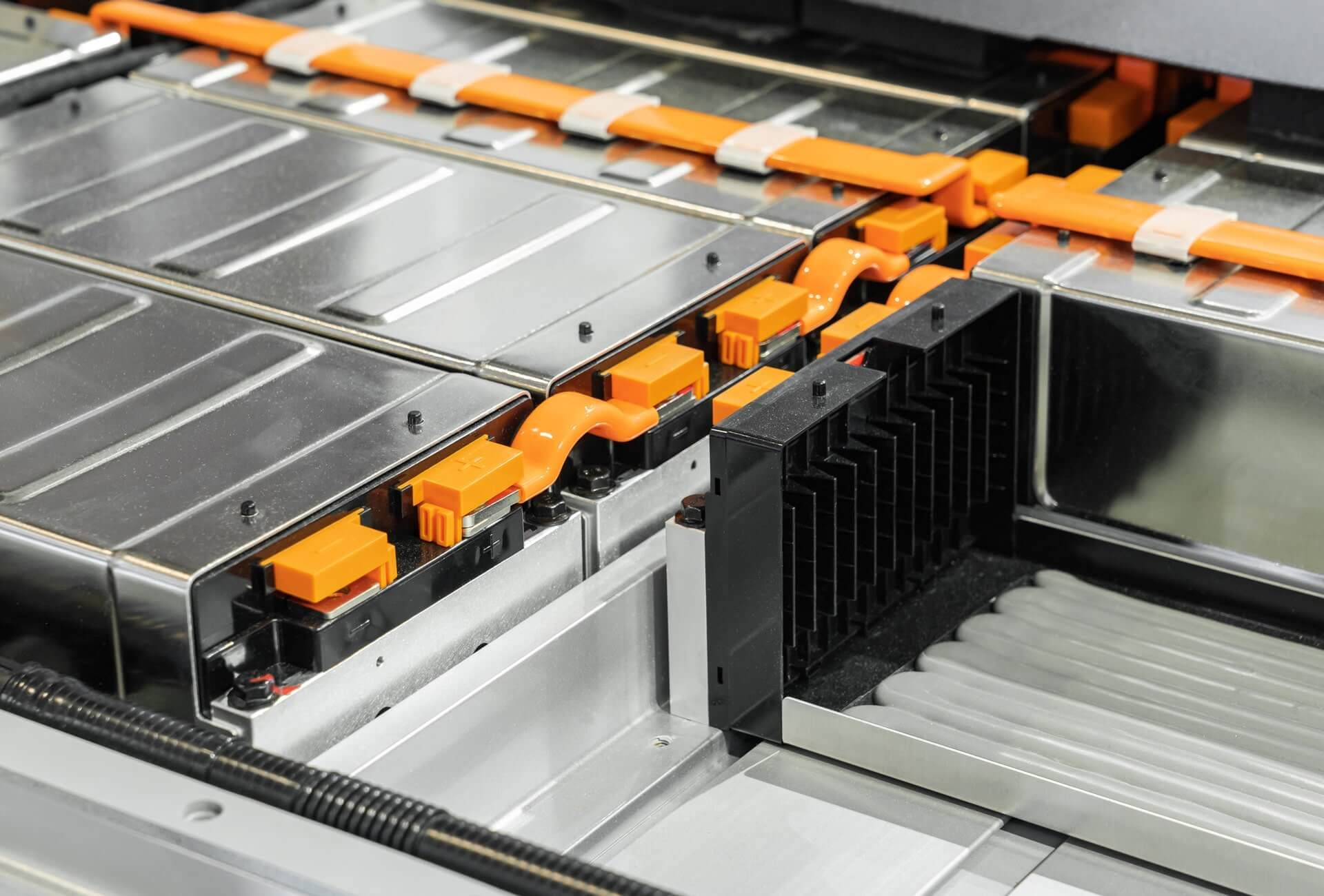

High-wattage devices like electric vehicle motors or industrial heaters demand batteries capable of sustaining high discharge rates. However, excessive wattage can generate heat, risking thermal runaway in poorly designed systems. Vade Battery’s UL-certified lithium polymer batteries incorporate flame-retardant materials and multi-layer protection circuits to mitigate these risks.

Advantages of Low-Wattage Devices

Low-wattage electronics, such as IoT sensors or GPS trackers, prioritize energy efficiency. Our ultra-low-temperature Li-ion batteries operate reliably in sub-zero environments, delivering stable power for devices as low as 10mW.

Balancing Power and Efficiency

Selecting the right battery involves matching wattage requirements with runtime needs. For example, a 48V golf cart battery system might require 2,000W for acceleration but only 500W for cruising. Vade Battery’s custom voltage configurations ensure optimal balance between power output and energy density.

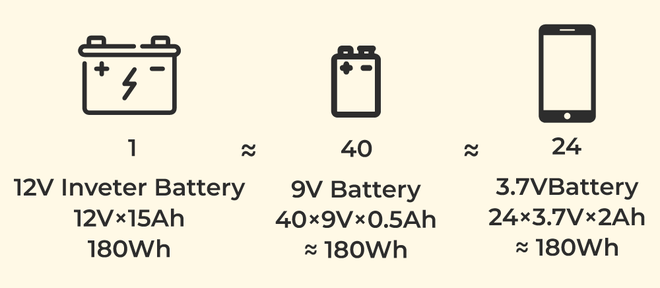

Watts vs. Watt-Hours: Understanding Energy vs. Power

Defining Watt-Hours in Battery Systems

Watts measure instantaneous power, while watt-hours (Wh) quantify total energy consumed or stored over time. For example, a 100-watt device running for 3 hours consumes 300 watt-hours. This distinction is critical for sizing battery systems, as energy capacity (Wh) determines runtime, while power (W) defines instantaneous load capability.

Vade Battery’s lithium-ion battery packs specify both metrics to ensure compatibility with high-power devices and long-duration applications.

Calculating Energy Consumption

To estimate energy needs:

- List all devices and their wattage.

- Multiply each device’s wattage by its daily runtime.

- Sum results to determine total daily watt-hours.

For instance, a 50W marine GPS running 24/7 consumes 1,200Wh daily. Pair this with a solar system and a 48V lithium battery to ensure uninterrupted operation.

Real-World Applications in Battery Design

High-energy-density batteries, like Vade’s LiFePO4 systems, prioritize watt-hours for applications requiring extended runtime, such as off-grid solar storage. In contrast, high-power batteries focus on wattage for short bursts, like drone propulsion.

Selecting the Right Power Supply for Your System

Matching Power Supply to Device Requirements

A power supply’s wattage must exceed the total load of all connected devices. For example, a 500W industrial sensor array requires a 600W power supply (20% headroom). Undersized supplies risk overheating, while oversized ones waste energy.

Vade Battery’s custom voltage configurations allow precise alignment with device specifications, whether 12V for automotive systems or 72V for industrial equipment.

Importance of Headroom in Battery Systems

Including 10–20% extra capacity accommodates unexpected surges and prolongs battery life. For example, a 24V motor rated for 200W should pair with a 240W+ battery. Our lithium polymer batteries feature built-in surge protection to handle brief overloads safely.

Case Study: Industrial Power Supply Solutions

A manufacturing client needed a 5kW battery system to power robotic arms. Vade delivered a modular LiFePO4 pack with 6,000W peak capacity, ensuring reliable operation during high-torque movements. The system’s BMS monitored real-time loads to prevent overloads.

Why Watts Are Critical in Marine and RV Applications

Calculating Power Needs for Marine Systems

Boat electronics (e.g., fish finders, trolling motors) vary widely in wattage:

- A 30W navigation light vs. a 1,500W bow thruster.

- Total daily energy needs = sum of (wattage × runtime) for all devices.

Vade’s ultra-low-temperature Li-ion batteries support marine applications with stable output in harsh conditions.

Managing Multiple Appliances in RVs

Running an AC (1,500W), microwave (1,000W), and lights (100W) simultaneously requires a 2,600W+ power source. Lithium batteries outperform lead-acid in RV applications due to higher discharge rates and compact size.

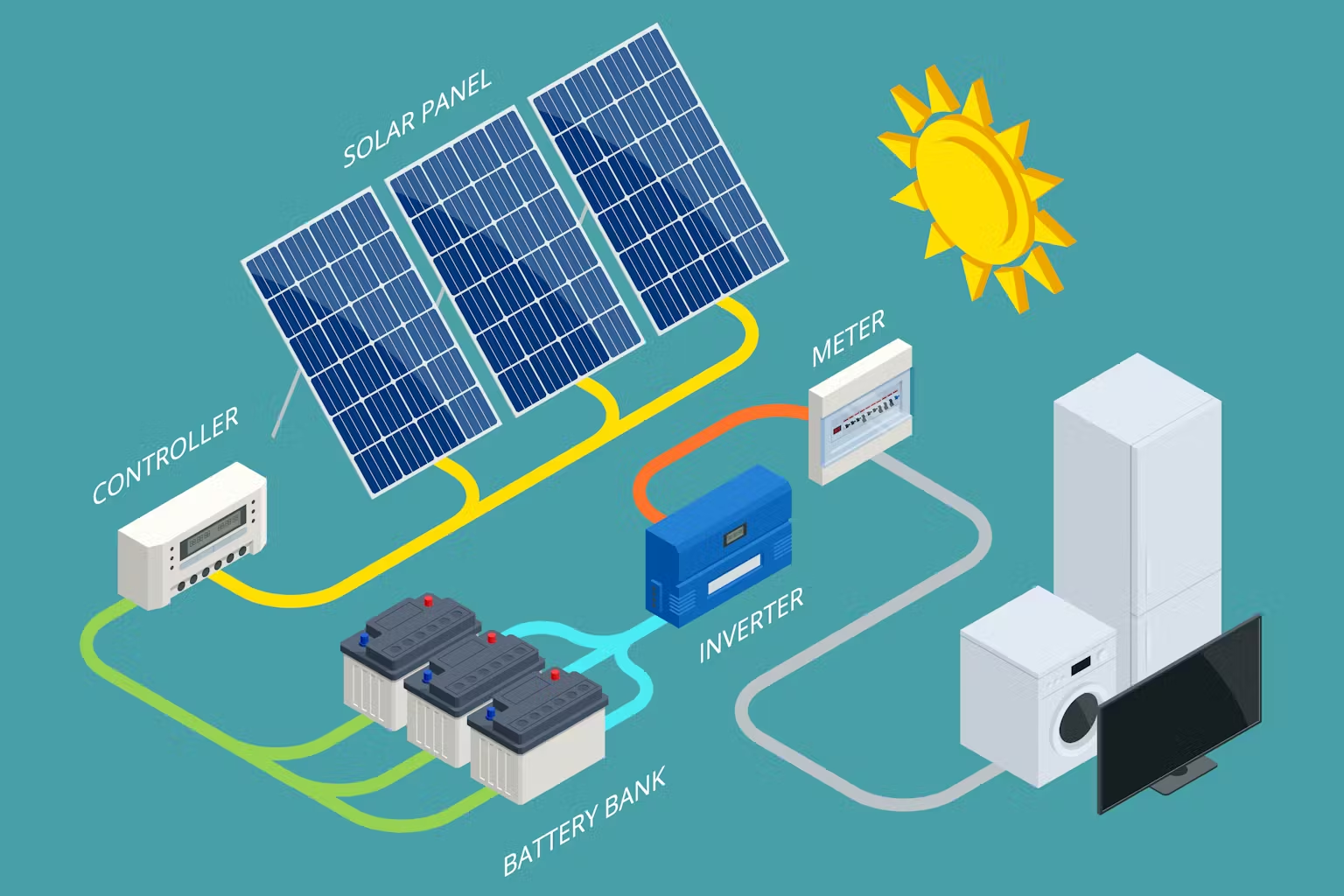

Solar Integration for Off-Grid Scenarios

Pair solar panels with a battery bank to store excess energy. For example, 800W of solar panels can recharge a 24V lithium battery during daylight to power nighttime loads.

Solar Power Calculations for Off-Grid Systems

Step-by-Step Solar Wattage Calculation

- Total daily watt-hours: Calculate as shown earlier.

- Sunlight hours: Divide daily watt-hours by local peak sun hours.

- Example: 3,000Wh ÷ 5 sun hours = 600W solar array.

- Battery storage: Size batteries to cover 1–3 days of autonomy.

Adjusting for Environmental Factors

- Reduce efficiency by 20–30% for cloudy climates.

- Use tilt mounts to maximize sunlight exposure.

- Our solar-compatible battery packs include MPPT charge controllers for optimized energy harvesting.

Battery Storage Solutions for Solar Energy

Vade’s modular lithium systems scale from 12V cabins to 48V off-grid homes. A 51.2V battery paired with 5kW solar panels can power a small workshop indefinitely.

Conclusion

Understanding watts and watt-hours enables engineers to design safer, more efficient battery systems. At Vade Battery, we combine UN 38.3-certified cells, precision BMS, and customizable configurations to meet exact power and energy needs—whether for a 10mW medical implant or a 100kW industrial backup system.

For tailored solutions, explore our custom battery design service or contact our team at service@vadebattery.com.