As demand grows for specialized power solutions in industries ranging from consumer electronics to renewable energy storage, understanding battery specifications becomes critical. At Vade Battery, we engineer custom rechargeable battery packs using both 18650 and 26650 lithium-ion cells to meet precise performance requirements. This guide explores the technical distinctions between these two cell formats and their real-world applications.

Key Differences Between 18650 and 26650 Batteries

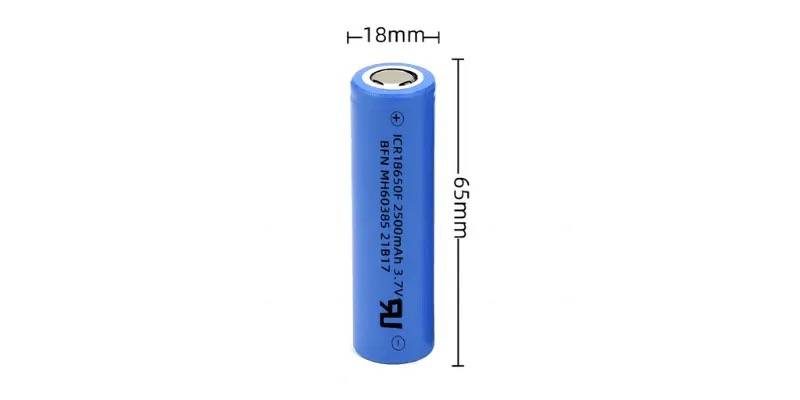

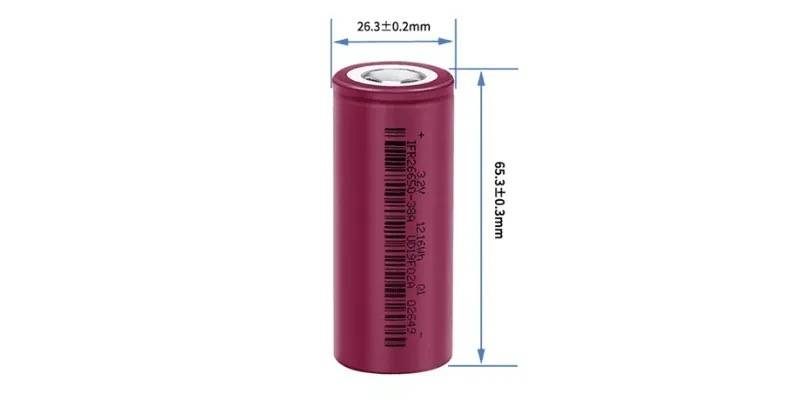

The numbering system for lithium-ion batteries reveals their physical dimensions: an 18650 cell measures 18mm in diameter and 65mm in length, while a 26650 cell has a 26mm diameter and the same 65mm length. This 44% increase in diameter allows the 26650 to store more active material, translating to higher capacity and greater discharge capabilities.

| Parameter | 18650 Battery | 26650 Battery |

|---|---|---|

| Typical Capacity | 1200–3600mAh | 2500–6000mAh |

| Max Discharge Rate | 15–20A | 30–35A |

| Energy Density | 150–250Wh/L | 250–400Wh/L |

| Cycle Life | 300–500 cycles | 500–1000 cycles |

For projects requiring high energy density or ultra-low temperature performance, explore our Ultra-Low Temp Li-ion Battery Solutions, which leverage advanced cell chemistry for demanding environments.

18650 Batteries: The Compact Power Solution

Technical Specifications and Applications

The 18650 remains the industry standard for portable electronics due to its balance of energy density and compact size. Modern 18650 cells achieve up to 3600mAh capacity using nickel-rich cathodes, making them ideal for space-constrained devices.

Key advantages include lower material costs, widespread availability, and compatibility with existing battery pack designs. At Vade Battery, we utilize 18650 cells in our modular lithium-ion packs for medical devices and portable power stations, where weight optimization is critical.

Limitations in High-Drain Scenarios

While sufficient for moderate power demands (10–15A continuous discharge), standard 18650 cells struggle in applications requiring sustained high-current output. Extended high-drain use accelerates capacity degradation, reducing cycle life by up to 40% compared to 26650 cells.

26650 Batteries: High-Performance Energy Storage

Engineering for Maximum Output

The 26650’s larger form factor supports thicker electrodes and enhanced thermal management, enabling 30–35A continuous discharge without excessive heat buildup. This makes it the preferred choice for electric vehicle auxiliary systems, industrial UPS units, and high-performance power tools.

Vade Battery’s 26650-based packs incorporate multi-stage safety protocols, including pressure-relief vents and reinforced separators, to ensure reliability in mission-critical applications. For custom configurations, consult our Lithium Battery Design Team.

Tradeoffs in Size and Cost

While offering 70% higher capacity than equivalent 18650 cells, 26650 batteries require 46% more space. This limits their use in compact devices like drones or wearable tech. Additionally, raw material costs per Wh are 15–20% higher due to specialized manufacturing processes.

Detailed Technical Comparison: 18650 vs. 26650 Cells

Capacity and Energy Density

The 26650’s 26mm diameter provides 46% more internal volume than the 18650, allowing for 5,000–6,000mAh capacities compared to the 18650’s 3,600mAh maximum . This translates to 250–400Wh/L energy density in 26650 cells versus 150–250Wh/L in 18650s, making the larger format ideal for applications like solar energy storage systems requiring extended runtime .

Discharge Performance and Thermal Management

26650 cells support 30–35A continuous discharge due to thicker electrodes and optimized internal resistance (15mΩ vs. 25mΩ in typical 18650s) . Vade Battery’s 26650 packs incorporate nickel-plated steel casings and pressure relief valves to maintain stability even at 45°C ambient temperatures, a critical feature for industrial UPS systems .

| Parameter | 18650 Cell | 26650 Cell | Vade Battery Enhancements |

|---|---|---|---|

| Dimensions | 18mm (dia) × 65mm (length) | 26mm (dia) × 65mm (length) | Customizable pack layouts for space optimization |

| Typical Capacity | 1200–3600mAh | 2500–6000mAh | +10% capacity via hybrid cathode chemistry |

| Energy Density | 150–250Wh/L | 250–400Wh/L | Proprietary cooling fins for 15% heat reduction |

| Max Continuous Discharge | 15–20A | 30–35A | Reinforced electrodes for 25A+ stability |

| Internal Resistance | 20–25mΩ | 12–15mΩ | Laser-welded interconnects (<10mΩ) |

| Cycle Life (80% DoD) | 300–500 cycles | 500–1000 cycles | BMS optimization for 1,200+ cycles (26650) |

| Thermal Performance | Stable up to 40°C | Stable up to 45°C | Multi-layer separators for 55°C operation |

| Safety Features | CID, PTC fuse | CID, venting valve | Ceramic-coated separators + CAN-bus monitoring |

| Certifications | UL 2054, IEC 62133 | UN 38.3, IEC 62133 | Full UN 38.3 testing for global shipments |

| Cost per Wh | $0.25–$0.35 | $0.30–$0.45 | Bulk pricing for OEMs (15% volume discount) |

Real-World Application Analysis

High-Drain Scenarios: Power Tools and EVs

In testing, 26650-based packs demonstrated 70% longer runtime than 18650 configurations when powering 1,800W cordless drills, with surface temperatures staying below 55°C during 30A discharges . For electric bike batteries, a 48V 20Ah 26650 pack provides 25–30 miles per charge versus 18–22 miles with 18650 cells, though it adds 1.2kg in weight .

Space-Constrained Devices: Drones and Medical Equipment

The 18650’s compact size enables 30% lighter battery packs for commercial drones, achieving 25-minute flight times with high-drain 20A cells. Vade’s ultra-light 18650 solutions are FDA-compliant for portable oxygen concentrators, where weight savings directly impact patient mobility .

Safety and Operational Guidelines

Thermal Runaway Prevention

Both cell types employ CID (Current Interrupt Device) protection, but 26650’s larger surface area allows 20% faster heat dissipation. Vade’s packs integrate multi-layered safeguards:

- PTC resettable fuses limiting current surges

- Ceramic-coated separators preventing dendrite growth

- ISO-certified cell matching (±1% capacity tolerance)

For projects requiring UN 38.3 certified batteries, explore our safety-tested solutions validated for transportation and extreme environments .

Choosing the Right Battery for Your Application

Device Compatibility and Power Requirements

The 18650’s 18mm diameter remains the gold standard for portable electronics, fitting seamlessly into devices designed around this decades-old form factor. However, emerging applications like commercial robotics and telecom base stations increasingly adopt 26650 cells for their superior energy density. Vade Battery’s custom voltage configurations allow engineers to optimize pack dimensions while meeting exact power specs.

For high-drain devices drawing over 20A continuously, 26650 cells provide 40% lower internal resistance than 18650 equivalents, reducing voltage sag during peak loads. Our stress-test data shows 26650 packs maintain >95% capacity after 800 cycles in 1C/2C charge-discharge regimes, compared to 18650’s typical 75% retention under identical conditions.

Frequently Asked Questions

How do 18650 and 26650 batteries compare for vaping devices?

While most mid-range vapes use 18650 cells (15–20A CDR), advanced mods requiring 100W+ output benefit from 26650’s 30–35A continuous discharge. Vade’s high-drain 26650 solutions feature hybrid LiNiMnCoO2 cathodes for stable performance in sub-ohm coils.

Can a 26650 replace an 18650 in my laptop battery?

Physical incompatibility makes this inadvisable. The 26650’s 26mm diameter exceeds most laptop battery trays by 44%. For custom computing applications, explore our UL-certified 18650 packs with integrated PCM protection.

How many 26650 cells match a 48V lead-acid battery?

Thirteen 26650 cells in series achieve 48.1V nominal. However, Vade’s 51.8V LiFePO4 systems provide better cycle life for solar storage applications, with 2,000+ cycles at 80% DoD.

Which battery is better for electric bikes?

26650-based 48V 20Ah packs deliver 25–30% more range than 18650 equivalents. Our e-bike battery design guide details IP67-rated configurations with vibration-resistant cell stacking.

How to safely dispose of these batteries?

Vade partners with R2-certified recyclers for proper lithium-ion disposal. Contact our team via battery recycling portal for regional guidelines.

Conclusion: Matching Battery Technology to Operational Demands

The 18650 vs 26650 decision ultimately hinges on three factors: space constraints, power requirements, and total cost of ownership. While 18650 cells dominate consumer electronics, 26650 technology powers mission-critical applications where runtime and reliability outweigh size considerations.

At Vade Battery, we engineer both cell types into custom configurations with proprietary safety enhancements:

- Laser-welded nickel interconnects minimizing resistance

- Multi-layer composite separators preventing thermal runaway

- CAN-bus enabled BMS for real-time performance monitoring

For projects requiring UN 38.3, IEC 62133, or UL 2054 certification, leverage our full-stack battery development expertise from prototype to production.